China OEM Automatic Injection Moulding Machine Products - Doorbell plastic parts injection moulding – Mestech

Short Description:

China OEM Automatic Injection Moulding Machine Products - Doorbell plastic parts injection moulding – Mestech Detail:

The shell of the doorbell is made of plastic. Therefore, the injection molding of doorbell plastic parts is also an important step in doorbell manufacturing.

As the most common household equipment in life, doorbell has many types. According to the signal transmission mode, there are wired doorbell and wireless doorbell. The wireless doorbell includes wireless visual doorbell and wireless non visual doorbell. Among them, wireless non visual doorbell and wired doorbell which we call ordinary doorbell are most widely used.

The doorbell is generally divided into two parts: the outdoor unit and the indoor unit. They are composed of electronic components and housing, keys, brackets and light guide parts. These plastic parts play an important role in providing space, protection, fixation and operation for doorbells. These housing, keys, brackets and light guide parts are usually injection molded parts. These plastic parts play an important role in providing space, protection, fixing and operation for doorbells.

1. Plastic components of outdoor unit

(1).Outdoor unit with switch

(2).Touch outdoor unit

(3).Outdoor unit with intercom function

(4).Outdoor unit with lens

(5),Outdoor unit with access control

2. Plastic components of indoor unit

(1).Indoor unit with Bell

(2).Indoor unit with flash

(3).Indoor unit with intercom

(4).Indoor unit with telephone

(5).Indoor unit with access control

(6).Desktop walkie talkie

Selection of plastic resin for doorbell

As a common household electronic products, consumers hope that doorbell is not only economical and practical, but also needs beautiful products, so as to play a decorative role in the surrounding families. Therefore, higher requirements are put forward for the appearance quality of products.

ABS is usually used to make doorbell shell, key and internal bracket, while PC is used for lamp post, lampshade, transparent ring and lens protective lens.

Injection molded parts and doorbells

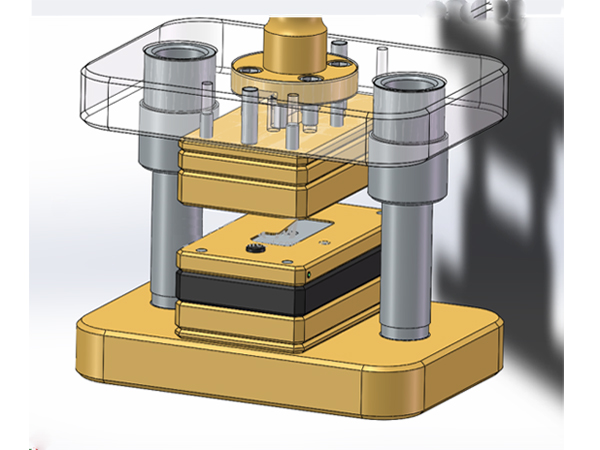

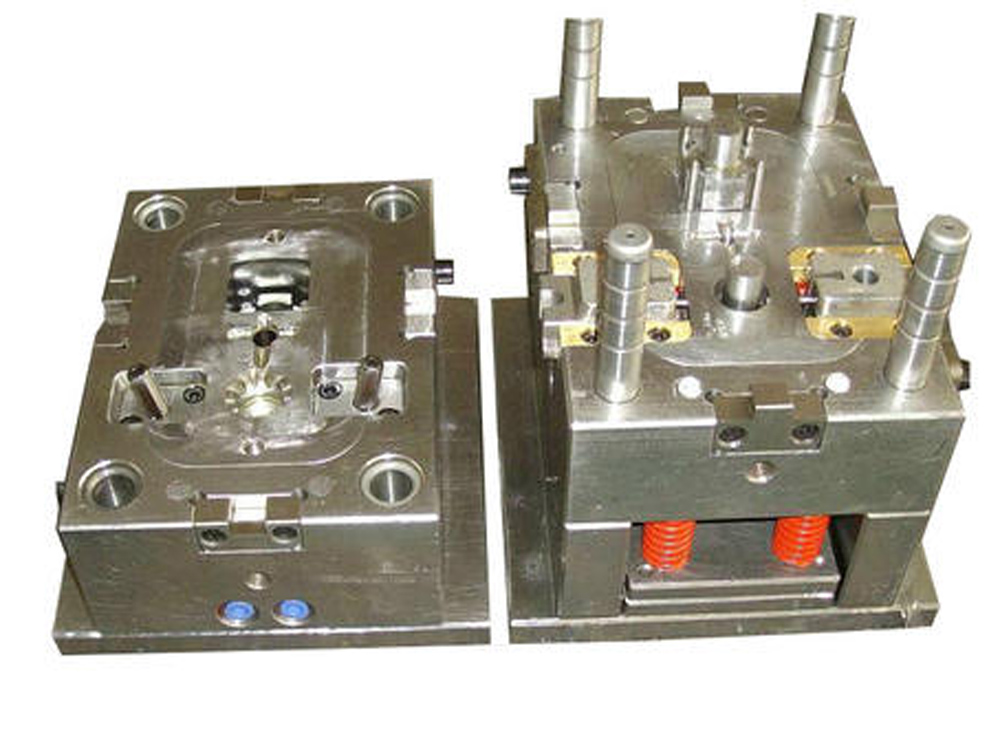

(1) Doorbell shell, key, lampshade and other parts mostly choose high gloss surface. No fusion line, water inlet, air line and parting line are required on the surface. Therefore, the die material usually needs to select high-quality steel, and the mold cavity surface needs to be precision polished. Parting lines, scars and parting lines on the mold surface should be avoided.

(2) There is a great demand for ordinary doorbell, and there are many companies engaged in the production of doorbell, and the market competition is fierce. In order to improve the production efficiency and reduce the cost, the doorbell injection mold often needs to use a porous, and through the automatic assembly line production

As a long-term experienced professional plastic mold and injection molding manufacturer, Mestech has long-term experience in providing customers with the production and injection molding of doorbell plastic parts. If you need, please contact us.

Product detail pictures:

Related Product Guide:

Cooperation

Our pursuit and enterprise goal is to "Always satisfy our customer requirements". We keep on to establish and style and design outstanding top quality goods for both our outdated and new prospects and realize a win-win prospect for our clientele likewise as us for China OEM Automatic Injection Moulding Machine Products - Doorbell plastic parts injection moulding – Mestech, The product will supply to all over the world, such as: Monaco, Manchester, Cyprus, With the superior and exceptional service, we are well developed along with our customers. Expertise and know-how ensure that we are always enjoying the trust from our customers in our business activities. "Quality", "honesty" and "service" is our principle. Our loyalty and commitments remain respectfully at your service. Contact Us Today For further information, contact us now.

Customer service staff and sales man are very patience and they all good at English, product's arrival is also very timely, a good supplier.