China OEM Die Casting & Stamping Products - Metal stamping molds – Mestech

Short Description:

China OEM Die Casting & Stamping Products - Metal stamping molds – Mestech Detail:

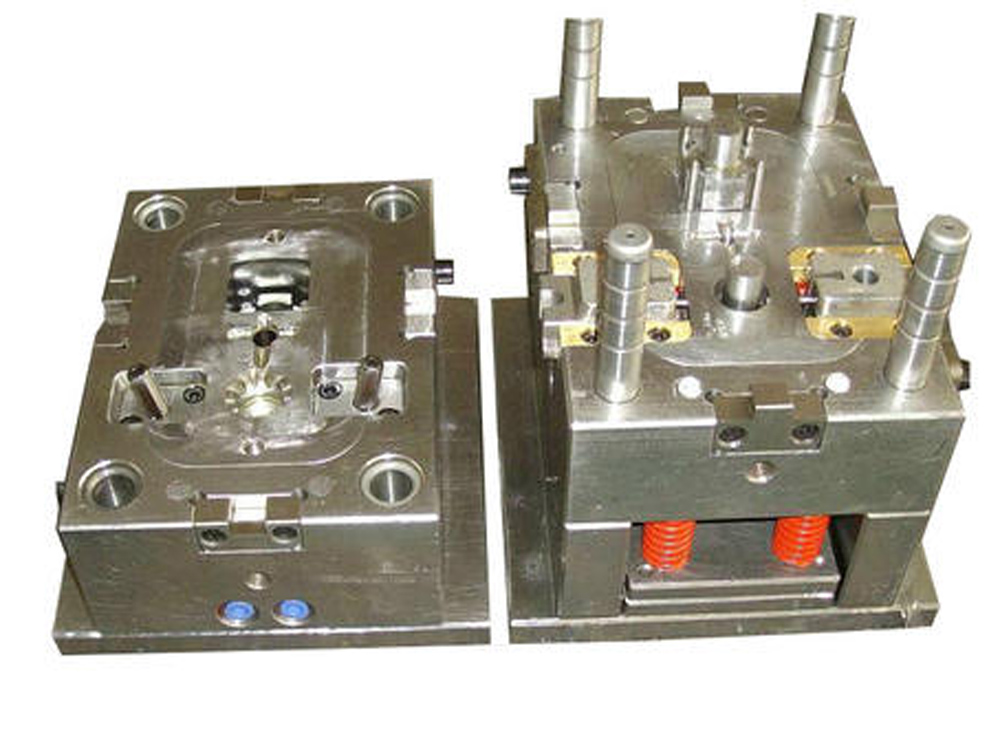

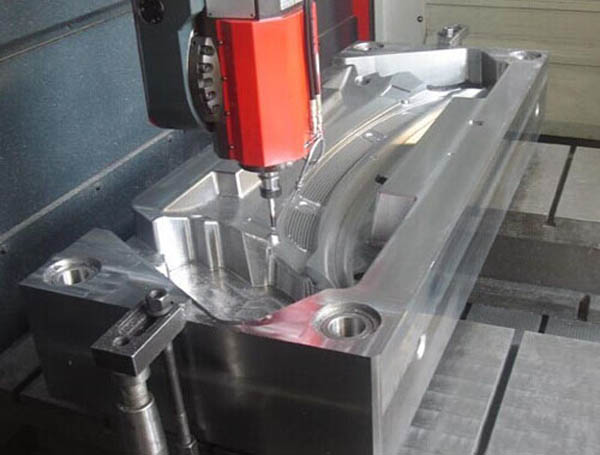

Metal stamping mold ( Metal stamping die) is a kind of special process equipment which processes materials (metal or non-metal) into parts (or semi-finished products) in cold stamping process. It is called cold stamping die (commonly known as cold stamping die). Stamping die mold is a cold working die mold. At room temperature, the die installed on the press is used to exert pressure on the material to produce separation or plastic deformation, so as to obtain the required parts.

Stamping metal parts account for a large proportion of metal parts, such as computer case, aluminum shell, equipment cover, toolbox, container, bracket, electronic shield cover, wire terminal and so on. Stamping die is a kind of mass production die, which has many forms. Stamping dies are usually classified according to process properties and die construction

Classification according to process properties

(1) (1) Blanking die is a die used to separate materials along closed or open contours . Such as blanking die, punching die, cutting die and so on.

(2) The bending die makes the blank or other blank produce bending deformation along the straight line (bending curve), so as to obtain a certain angle and shape of the workpiece mold.

(3) Drawing die is a die which can make blank into open hollow part or make hollow part change shape and size further.

(4) The forming die is a kind of die which can directly copy the blank or semi-finished workpiece according to the shape of the punch and the die, while the material itself only produces local plastic deformation. Such as bulging die, necking die, expanding die, rolling forming die, flanging die, shaping die, etc.

(5) Riveting die is to use external force to make the parts join or lap together in a certain order and way, and then form a whole.

(3) Progressive stamping die (also called continuous die mold)

In the feeding direction of the blank, there are two or more stations. In one stroke of the press, two or more stamping processes are completed in different stations one by one.

The features of progressive die are as follows:

A. High production efficiency: progressive die can complete the stamping, flanging, bending, drawing, three-dimensional forming and assembly of complex parts, reducing the intermediate transfer and repeated positioning. Moreover, the increase of the number of stations does not affect the production efficiency, and it can make very small precision parts. Easy to automate production.

B. Low production cost: the production efficiency of progressive die is high, the number of presses is small, the number of operators and workshop area are small, which reduces the storage and transportation of semi-finished products, so the comprehensive production cost of product parts is not high.

C. Long mold life: complex internal and external shapes can be divided into simple male and female die shapes, which can be cut step by step. The working procedure can be scattered in several stations, and the space can be set in the area where the working procedure is concentrated, so as to avoid the problem of too small wall thickness of male and female dies, change the stress state of male and female dies, and improve the die strength. In addition, the progressive die also uses the discharge plate as the punch guide plate, which is very beneficial to improve the die life.

D. High manufacturing cost of mold: progressive die has high manufacturing cost because of its complex structure, high manufacturing accuracy, long cycle and low material utilization. Application: it is suitable for mass production of small and medium size with complex structure.

Progressive die

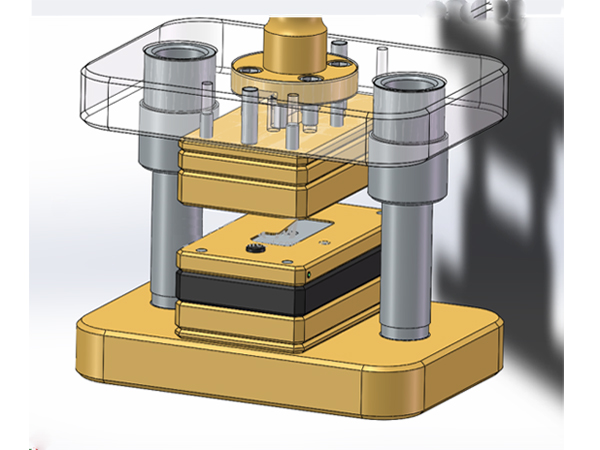

(4) Transfer stamping mold (multi position transfer mold):

it integrates the characteristics of single process stamping mold and progressive stamping mold. By using the manipulator transfer system, it can realize the rapid transfer of products in the mold. It can greatly improve the production efficiency of products, reduce the production cost of products, save the material cost, and the quality is stable and reliable. It includes the following features:

A. Use on the multi stations punch machine.

B. Each station is a complete engineering mold, complete a specific process, called sub mold. There are some relations among sub-molds. Each sub-mold can be adjusted independently without affecting the front and back sub-molds.

C. The transfer of parts between sub-molds is realized by manipulator. The multi position transfer die is suitable for automatic production and computer intelligent detection and management. It is used in the production of parts with high precision, high quality and complex structure.

Application of molds or dies:

(1). Electronic and communication products;

(2). Office equipment;

(3). Automobile spare parts;

(4). Household appliances;

(5).Electrical equipment;

(6). Medical and environmental protection;

(7). Industrial facilities;

(8).Artificial intelligence;

(9). Transportation;

(10). Building materials, kitchen and toilet equipment and tools;

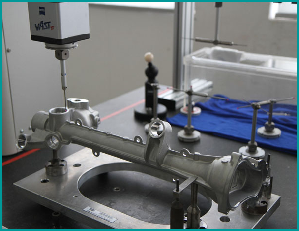

Product detail pictures:

Related Product Guide:

Cooperation

"Sincerity, Innovation, Rigorousness, and Efficiency" will be the persistent conception of our company to the long-term to establish together with customers for mutual reciprocity and mutual gain for China OEM Die Casting & Stamping Products - Metal stamping molds – Mestech, The product will supply to all over the world, such as: Canberra, Latvia, Wellington, To achieve reciprocal advantages, our company is widely boosting our tactics of globalization in terms of communication with overseas customers, fast delivery, the best quality and long-term cooperation. Our company upholds the spirit of "innovation, harmony, team work and sharing, trails, pragmatic progress". Give us a chance and we will prove our capability. With your kind help, we believe that we can create a bright future with you together.

After the signing of the contract, we received satisfactory goods in a short term, this is a commendable manufacturer.