China OEM Electric Injection Molding Machine Manufacturers - Video phone plastic enclosure – Mestech

Short Description:

China OEM Electric Injection Molding Machine Manufacturers - Video phone plastic enclosure – Mestech Detail:

Video phone is composed of telephone, camera, TV receiving and displaying equipment and controller. Video phone and ordinary telephone are used to talk; the function of camera equipment is to capture the image of the user and transmit it to the other side; the function of television reception and display equipment is to receive the image signal of the other side and display the image of the other side on the screen.

Plastic parts and materials of videophone plastic enclosure

1. Upper case:

It is used to place the fixed number key letter key, as well as receive, dial out, sound size, image brightness adjustment, lens adjustment and other functional operation keys

Cradle for microphone handle

Used to protect internal electronic components

Material: ABS or PC / ABS

2. Microphone handle: used for voice answering and intercom. Material ABS

3. Base case: it is matched with the front case to contain and protect PCBA components, button PCBA, power interface, audio and video interface

Material: ABS

4. Display screen cases: fixed and protected image display screen, camera lens.

(1). Front cover: PC / ABS

(2). Rear case: PC / ABS or ABS

5. Numbers, letters and operation keys

Material: ABS, PC or silicone key

6. Other parts such as internal frames, etc

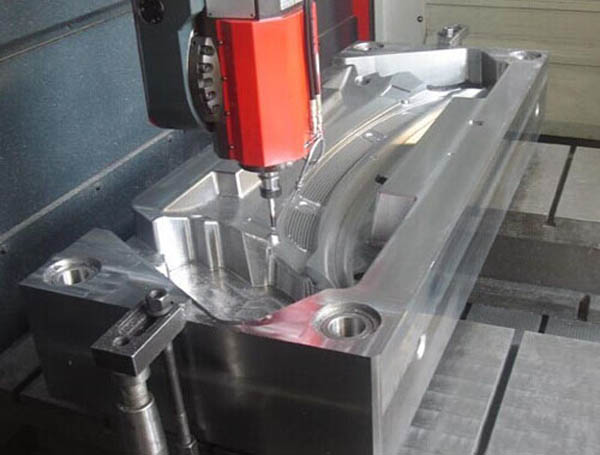

Injection molding process characteristics of plastic parts of videophone:

1. The upper case, display screen and microphone of the base machine are appearance parts, which have high requirements for appearance quality of parts. Shrinkage, fusion lines and air marks are not allowed.

2. The upper case, the bottom case, the front cover and the rear housing of of the display screen with large dimensions are easy to deform. When designing, the thickness of the parts should be enough. In addition, the injection position of the mold should be selected correctly so that the plastic can be filled evenly and deformation can be avoided.

3. The keys can be plastic injection molding, generally using silica gel key, or silica gel + plastic key.

We warmly welcome friends who are engaged in the research and development and manufacture of videophone to contact us, and we will provide you with professional services in injection moulding of plastic parts.

We warmly welcome friends who are engaged in the research and development and manufacture of videophone to contact us, and we will provide you with professional services in injection moulding of plastic parts.

Product detail pictures:

Related Product Guide:

Cooperation

To fulfill the customers' over-expected fulfillment , we have now our solid staff to deliver our greatest general assistance which includes internet marketing, product sales, creating, manufacturing, excellent controlling, packing, warehousing and logistics for China OEM Electric Injection Molding Machine Manufacturers - Video phone plastic enclosure – Mestech, The product will supply to all over the world, such as: Ghana, Oslo, Irish, We adopt advanced production equipment and technology, and perfect testing equipment and methods to ensure our product quality. With our high-level talents, scientific management, excellent teams, and attentive service, our merchandise are favored by domestic and foreign customers. With your support, we'll build a better tomorrow!

A good manufacturers, we have cooperated twice, good quality and good service attitude.