China OEM Hopper In Injection Moulding Factories - Plastic injection machine – Mestech

Short Description:

China OEM Hopper In Injection Moulding Factories - Plastic injection machine – Mestech Detail:

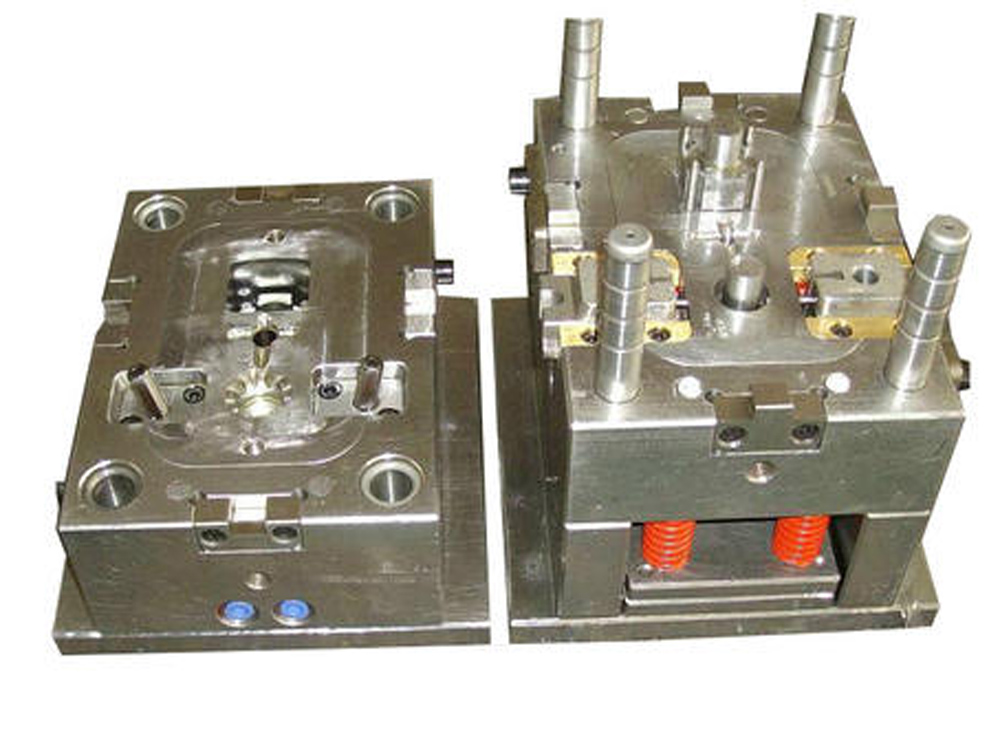

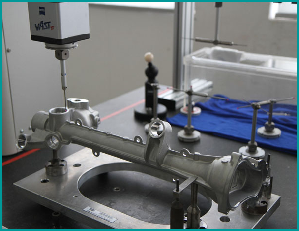

Plastic injection machine is also called injection molding machine or injection machine. It is the main molding equipment that makes thermoplastic or thermosetting plastic into plastic products of various shapes by using plastic molding molds. The functions of plastic injection molding machine is to heat plastics, apply high pressure to molten plastics, and make them shoot out and fill mold cavity.

I-The classification of plastic injection molding machine Plastic injection molding machine has the ability to shape plastic products with complicated appearance, precise size or dense texture with metal inserts at one time. It is widely used in national defense, electromechanical, automotive, transportation, building materials, packaging, agriculture, culture, education, health and people’s daily life. With the rapid development of plastics industry and the complex structure and functions of the moulding products, different types and specifications of injection moulding machines have been developed accordingly. According to the The precision of products produced, the injection machines can be divided into ordinary and precision injection molding machines. According to power and control system, the injection machine can be divided into hydraulic and all electric injection molding machines. According to the structural form of injection molding machine, there are three kinds: vertical and horizontal (including two color injection molding machine) and angle type.

The introduction to the characteristics of various injection molding machines

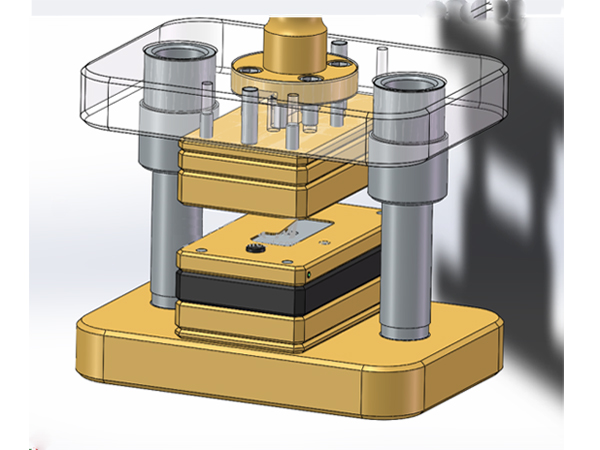

5. The general mold-locking device is open around, easy to configure all kinds of automatic devices, suitable for complex, sophisticated products of automatic molding.

6. the belt conveyance device is easy to realize the intermediate installation through the mould, so as to facilitate the automatic production.

7. it is easy to ensure consistency of resin flow and mold temperature distribution in mold.

8. Equipped with rotating table, moving table and inclined table, it is easy to realize insert molding and die combination molding.

9. small batch trial production, the mold structure is simple, low cost, and easy to uninstall.

10. vertical machine because of the low center of gravity, relatively horizontal seismic resistance is better.

Product detail pictures:

Related Product Guide:

Cooperation

Our target should be to consolidate and enhance the top quality and service of current goods, in the meantime frequently create new products to satisfy diverse customers' calls for for China OEM Hopper In Injection Moulding Factories - Plastic injection machine – Mestech, The product will supply to all over the world, such as: Morocco, South Africa, luzern, It using the world's leading system for reliable operation, a low failure rate, it suitable for Argentina customers choice. Our company is situated within the national civilized cities, the traffic is very convenient, unique geographical and economic conditions. We pursue a people-oriented, meticulous manufacturing, brainstorm, build brilliant" business philosophy. Strict quality management, perfect service, reasonable price in Argentina is our stand on the premise of competition. If necessary, welcome to contact us by our website or phone consultation, we will be happy to serve you.

We have been cooperated with this company for many years, the company always ensure timely delivery ,good quality and correct number, we are good partners.