China OEM Injection Moulding For Dummies Quotes - Electrical junction box and molding – Mestech

Short Description:

China OEM Injection Moulding For Dummies Quotes - Electrical junction box and molding – Mestech Detail:

Electrical junction boxes are widely used for transmission and distribution of power and communication. The main parts of the junction box shell and cover are mostly plastic produced by injection molding. The junction box needs to comply strict electrical performance standard, so we will introduce the electrical junction box and molding here.

What is plastic junction box ?

Electrical junction box is also called connecting box, terminal box, electrical connector, terminal base.

An electrical junction box is an enclosure housing electrical connections, to protect the connections and provide a safety barrier.

A small metal or plastic junction box may form part of an electrical conduit or thermoplastic-sheathed cable (TPS) wiring system in a building.

If designed for surface mounting, it is used mostly in ceilings, under floors or concealed behind an access panel – particularly in domestic or commercial buildings. An appropriate type (such as that shown on the left) may be buried in the plaster of a wall (although full concealment is no longer allowed by modern codes and standards) or cast into concrete – with only the cover visible.

Plastic electrical boxes have their pluses and minuses. Because they are plastic, there is no need to attach a ground wire to it. Since it is made of a non-conductive material, switches and outlets cannot short out if they touch the side of the box.

Plastic boxes usually come with tapped screw holes for easy attachment of switches and outlets. These boxes come in a single-gang, double-gang, and even multiple-gang configurations.

Types of electrical junction box

Electrical junction boxes types are various: indoor type , outdoor type, high voltage resistance type, and waterproof type. Materials and safety requirements vary from different environments and countries. Therefore the injection mold and forming processing are also different.

1. indoor electrical junction box.

Resin types: ABS, PVC

Most of these are office and home wiring boxes. They are used for indoor power distribution and centralized control, as well as on-off power supply, and communication line access and control. The general working voltage is below 250 volts. The plastic resin is required to comply with the flame retardant grade UL94 V1~V0 .

2. outdoor electrical junction box.

Resin types: ABS,ABS/PC

Outdoor junction box is required to be able to withstand the outdoor high and low temperature and rain moisture and sunlight aging corrosion, product structure waterproof, anti-ultraviolet radiation aging, adapt to high and low temperature environment. It is necessary to use high quality plastics, such as PC or nylon, with special additives with excellent ultraviolet resistance and high and low temperature performance.

3. Industrial junction box.

Resin types: ABS, ABS/PC, Nylon

Industrial junction box, often have a special performance requirements, such as dimensional accuracy and stability, oil and alkali resistance, wear resistance. Plastic materials should be selected for different requirements and mold accuracy should be determined.

4. high voltage resistance electrical junction box.

Resin types: ABS, ABS/PC, Nylon

The junction box is mainly used for high voltage environment, such as electrical cabinets, electrical control boxes, distribution devices. Good insulation and anti-aging properties are required. Nylon and other engineering plastics are generally selected.

5. The main function of the photovoltaic module junction box is to connect and protect the solar photovoltaic module, conducting the current generated by the photovoltaic module. As an important component of solar cell module, the junction box of photovoltaic module is a comprehensive product which integrates electrical design, mechanical design and material application. It provides users with a combined connection scheme of solar photovoltaic module.

6. Waterproof junction box.

Resin types: ABS, ABS/PC, PPO

There are two standards for waterproofing.

A. Short external splash, i.e. water will not be poured directly on the product.

B. The product is immersed in water.

Waterproof requirements mainly depend on the structure of plastic parts, such as:

Encrypt the sealing ring at the joint or opening;

Ultrasound welding of two joints:

Integral injection molding.

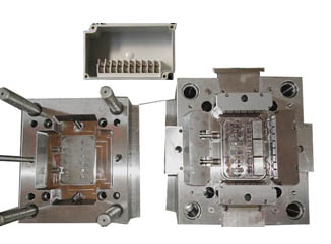

Product detail pictures:

Related Product Guide:

Cooperation

We're convinced that with joint endeavours, the business between us will bring us mutual benefits. We are able to guarantee you products high quality and competitive value for China OEM Injection Moulding For Dummies Quotes - Electrical junction box and molding – Mestech, The product will supply to all over the world, such as: azerbaijan, Belgium, Mozambique, Our company always committed to meet your quality demand, price points and sales target. Warmly welcome you open the boundaries of communication. It is our great pleasure to service you if you need a trusted supplier and value information.

On this website, product categories is clear and rich, I can find the product I want very quickly and easily, this is really very good!