China OEM Post Processing Of Plastic Parts Products - Plastic Syringe injection molding – Mestech

Short Description:

China OEM Post Processing Of Plastic Parts Products - Plastic Syringe injection molding – Mestech Detail:

Plastic syringes are common devices used in many fields, such as medical treatment, industry, agriculture, scientific testing and etc. The syringe is long and thin, and the fit between the syringe and the plunger requires good air tightness, The syringe is long and thin, and the fit between the syringe and the plunger requires good air tightness, so it has special requirements in mold making and injection molding process.

A syringe is a tube with a nozzle and a piston or bulb for sucking and ejecting liquids in a trickle, for cleaning wounds or cavities, or with a hollow needle to inject or extract fluid.

Early syringes were made of glass, which were expensive to make, fragile and portable. The appearance of disposable plastic syringe, which is easy to manufacture, low cost and easy to carry, avoids the risk of cross infection and greatly facilitates doctors and patients.

The syringe barrel is made of plastic or glass, usually with a scale indicating the amount of liquid in the syringe, and is almost always transparent. Glass syringes can be sterilized in autoclave. However, most modern medical syringes are plastic syringes with rubber pistons because of the much better sealing between the piston and the barrel, and they are cheap and can be discarded only once.

The application of plastic syringes

In medicine, syringes are used to inject drugs into the skin, blood vessels or lesions of patients, or to extract blood or body fluids from patients for laboratory examination.

Plastic syringes used in medical

Medical syringes are sometimes used without a needle for orally administering liquid medicines to young children or animals, or milk to small young animals, because the dose can be measured accurately and it is easier to squirt the medicine into the subject’s mouth instead of coaxing the subject to drink out of a measuring spoon.

Besides the use in medicine, syringes can be used in many other purpose. For example:

* To refill ink cartridges with ink in fountain pens.

* To add liquid reagents in the laboratory

* To add glue to the joint of two parts

* To feed lubricating oil to the machine

* To extract liquid

Plastic syringes used in industry and laboratory

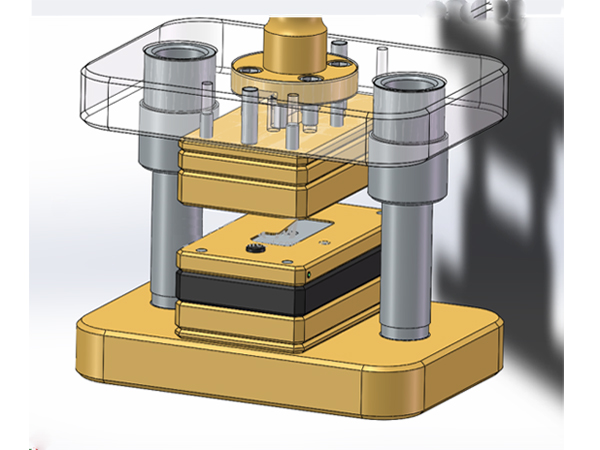

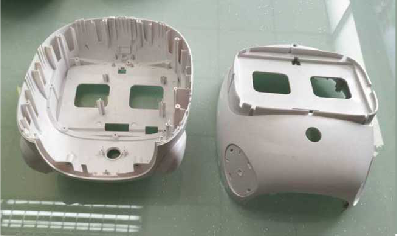

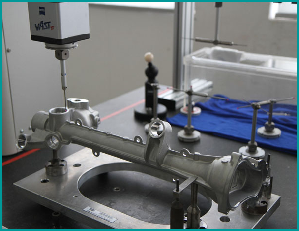

The body of a syringe is mainly composed of two parts: a plastic plunger, a plastic barrel. It’s long and straight. In order to ensure sealability, the diameter of the inner hole section of the whole needle barrel is usually kept at a dimension without drawing angle, and deformation is not allowed. So the injection mold and molding of the plastic barrels always require special techniques and skills .

Mestech can make injection moulds and injection production for various kinds of plastic syringe parts. We look forward to providing you with processing services in this area. Please contact us.

Product detail pictures:

Related Product Guide:

Cooperation

Normally customer-oriented, and it's our ultimate concentrate on for being not only one of the most dependable, trustable and honest supplier, but also the partner for our shoppers for China OEM Post Processing Of Plastic Parts Products - Plastic Syringe injection molding – Mestech, The product will supply to all over the world, such as: Australia, Grenada, Congo, Our company offers the full range from pre-sales to after-sales service, from product development to audit the use of maintenance, based on strong technical strength, superior product performance, reasonable prices and perfect service, we'll continue to develop, to deliver the high-quality items and services, and promote lasting cooperation with our customers, common development and create a better future.

The customer service staff's attitude is very sincere and the reply is timely and very detailed, this is very helpful for our deal,thank you.