China OEM Small Injection Molding Machine Factories - Audio speaker plastic housing – Mestech

Short Description:

China OEM Small Injection Molding Machine Factories - Audio speaker plastic housing – Mestech Detail:

Audio speakers ( also are called stereo speakers) are a large class of electroacoustic products. Their enclosure and internal structure section are mostly plastic parts, which are produced by injection moulding. So audio speaker plastic enclosure injection molds is much important tool for mass production of audio speaker product industry.

Audio speaker is the one of the most important equipment in sound system , which is generally composed of speaker unit and box body(enclosure). The speaker unit is used as the part of sound production, and the box is used as the supplement of the speaker unit to correct the sound.

The structure design, size, volume and appearance of speaker housings are different for different sounds frequency band, use occasions, power sizes and effects quality.

In order to get sound effect, the sound cavity and air duct are often designed inside the sound box.

The enclosure of a audio speaker includes box body, cover and baffle. The speaker body and the baffle play a very important role in the construction of the speaker. Baffle is usually integrated into the box body.

Production features of plastic housing of audio speakers:

1.Plastic material selection

The speaker plastic housing is required to accommodate and install the speaker and electronic components. The material is required to have a certain bearing strength and a certain rigidity to ensure the sound quality. Therefore, ABS is generally used as the shell. Transparent PC or PMMA panel will be used for speakers equipped with light decoration.

2.Part structure

In order to get sound effect, the sound cavity, air duct and lateral fixed structure are often designed in the sound box, which greatly increases the complexity parts structure and the difficulty of mold making. For some exquisite small digital speakers, we often use two-color injection molding, metal parts embedded injection molding and other processes.

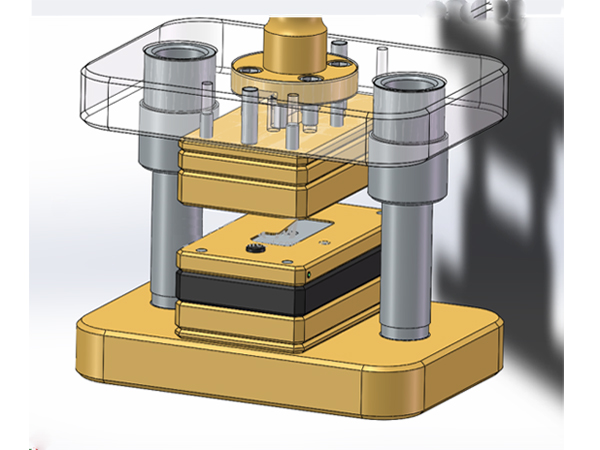

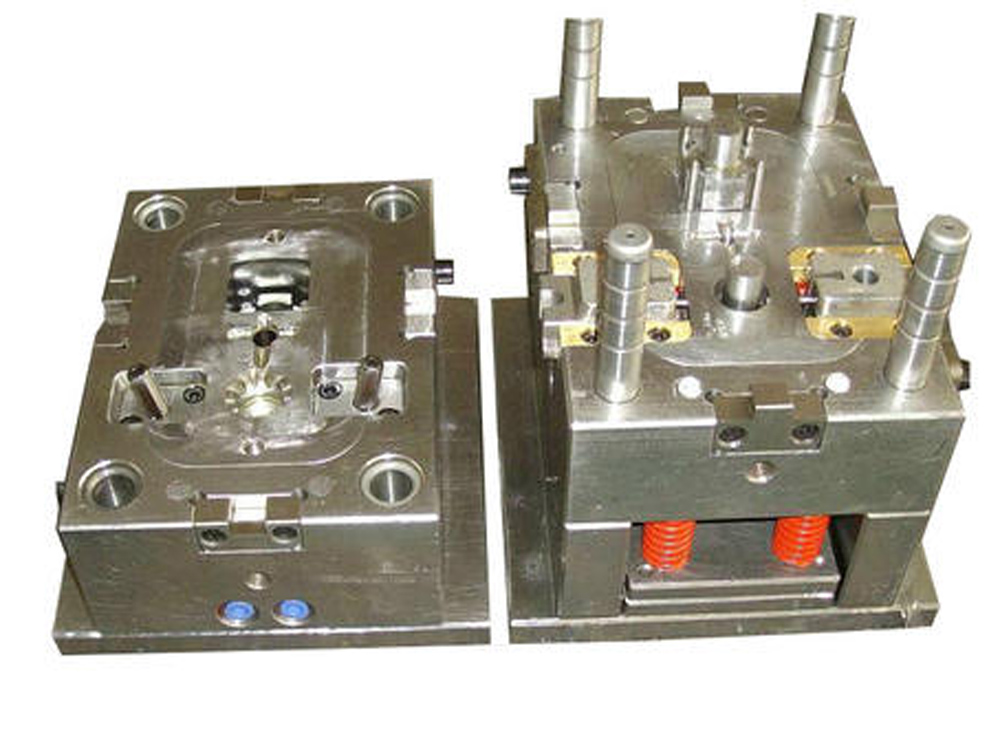

3.Characteristics of injection mold

The materials used for plastic parts on the speaker are common and general. Their injection molding process is similar to that of general plastic parts. At the same time, speakers, especially digital speakers, are generally in great demand in the market, requiring long service life and high productivity of the moulds to obtain low single piece cost.

4.Surface treatment

As a kind of consumer electronic product, the appearance of speaker is very important. The manufacturer gives plastic parts such as sunburn, high gloss, spray painting, vacuum plating, etc. to obtain beautiful appearance and attract customers to buy.

MESTECH has good technical strength, can provide customers with audio speaker enclosure injection mold manufacturing and injection production. If you have audio speaker enclosure need tooling and injection moulding, please feel free to contact us.

Product detail pictures:

Related Product Guide:

Cooperation

We have been experienced manufacturer. Wining the majority of your crucial certifications of its market for China OEM Small Injection Molding Machine Factories - Audio speaker plastic housing – Mestech, The product will supply to all over the world, such as: Seattle, Irish, Riyadh, The quality of our merchandise is equal to OEM's quality, because our core parts are the same with OEM supplier. The above items have passed professional certification, and we not only can produce OEM-standard items but we also accept Customized Merchandise order.

This company conforms to the market requirement and joins in the market competition by its high quality product, this is an enterprise that have Chinese spirit.