China OEM Vacuum Die Casting Products - CNC machining – Mestech

Short Description:

China OEM Vacuum Die Casting Products - CNC machining – Mestech Detail:

MESTECH is equipped with a number of high-performance CNC machining equipment, with an excellent team of design and machining engineers and rigorous process. We are honored to provide our customers with high quality products, timely delivery and services.

Machinery and equipment industry is the mother of modern industry. The industry that undertakes manufacturing machinery and equipment is the mechanical processing industry. The technical level of mechanical processing determines the quality level of machinery and equipment.

What is precision machining?

Machining is the manufacturing process of removing material from the workpiece to obtain the required shape and size. Machines used for mechanical processing are called machine tools. Materials for machined parts include steel, non-ferrous metals and other shapes and strength-stable metals, as well as solid plastics and wood products. Machining can achieve high precision parts, so we call it precision machining. It is the main processing method for manufacturing various machine parts.

With the development of computer technology, industrial digital control technology is introduced into machine tool equipment, which realizes the digitalization and automation of machine tool work and greatly improves production efficiency and processing accuracy. This kind of technology which uses computer system to operate machine tool processing is called numerical control processing technology. The machine tool which uses computer operating system is numerical control machine tool (CNC machine).

What is CNC Machining ?

CNC machining (precision machining) is a manufacturing process. Machine tools run under the control of computer programs. Computer programs are coded to move cutters to generate precision machined parts matching the size of the coded program (called G code).

CNC machining is a manufacturing process in which pre-programmed computer software indicates the movement of plant tools and machinery. This process can be used to control a series of complex machinery, from grinders and lathes to milling machines and routers. Through NC machining, three-dimensional cutting tasks can be completed in a set of prompts.

Usually, CAM (Computer Aided Manufacturing) software is used in machine shop to automatically read CAD (Computer Aided Design) files and generate G code program to control CNC machine tools.

What is CNC machining machine Tool ?

CNC machine tool is a machine tool which integrates general machine tool and computer system.

The machine tools controlled include grinders, milling machines, lathes, drills and planers.

In the process of CNC lathe processing, the determination of CNC processing route generally follows the following principles:

(1)The accuracy and surface roughness of the workpiece to be processed should be guaranteed.

(2)Make the processing route shortest, reduce the empty travel time and improve the processing efficiency.

(3)Simplify the workload of numerical calculation as much as possible and simplify the processing procedure.

(4)For some reusable programs, subroutines should be used.

The types of CNC machine tools:

1.CNC milling machines

2.CNC machining center.

3.CNC Lathes.

4.Electrical Discharge CNC Machines.

5.CNC Wire Cutting Machine

6.CNC precision grinding machine

The feature of CNC machining

CNC machine overcomes the discontinuity of manual operation of traditional mechanical tools. It has high efficiency, stable quality, precise size and automation. It is very suitable for high precision and high quality production. CNC machining is a necessary way to realize precision parts manufacturing.

The application of CNC machining

1. Reduce the number of fixtures and tools, and do not need complex fixture tools to process parts with complex shapes. If you want to change the shape and size of the parts, you only need to modify the parts processing procedures, which is suitable for the development and modification of new products.

2. The CNC processing quality is stable, the processing precision is high, the repetition precision is high, and it can meet the processing requirements of aircraft.

3. The production efficiency is higher in the case of multi-variety and small batch production, which can reduce the time of production preparation, machine tool adjustment and process inspection, and also reduce the cutting time due to the use of the best cutting quantity.

4. Machinable complex profiles which are difficult to be machined by conventional methods, and can even process some parts which can not be observed. In summary, it is the kind of precise parts with complex structure and small batches of products, such as precision axles, optical fiber tail shanks, pins and so on, that are more suitable.

Mestech company provides customers with the precision machining services of a variety of metal, plastic parts. If you want more information, please contact us.

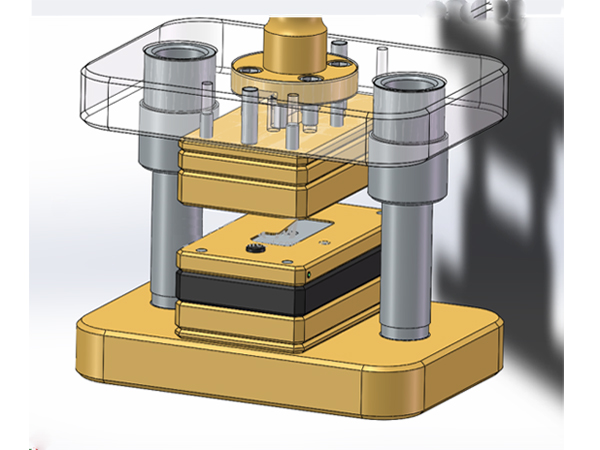

Product detail pictures:

Related Product Guide:

Cooperation

"Sincerity, Innovation, Rigorousness, and Efficiency" will be the persistent conception of our company to the long-term to establish together with customers for mutual reciprocity and mutual gain for China OEM Vacuum Die Casting Products - CNC machining – Mestech, The product will supply to all over the world, such as: Roman, Japan, Uzbekistan, We are committed to meet all your needs and solve any technical problems you may encounter with your industrial components. Our exceptional products and vast knowledge of technology makes us the preferred choice for our customers.

The factory can meet continuously developing economic and market needs, so that their products are widely recognized and trusted, and that's why we chose this company.