Die casting molds

Short Description:

Die casting mold is a kind of equipment for metal die casting. A die casting mold consists of mold “cover die half” and the other the “ejector die half.

Die-casting molds are mainly used for forming non-ferrous metal parts with complex structure and shape. Such as the mass production of aluminum alloy, zinc alloy, magnesium alloy and copper alloy parts, which are mostly used in automobile, electronics, electrical appliances, furniture, medical and other products.

What is die casting mold

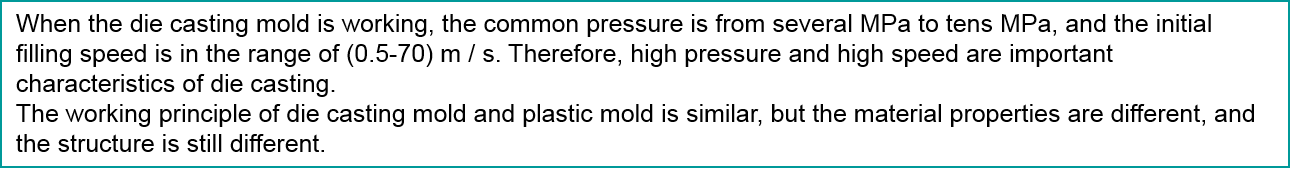

Die casting is the short name of pressure casting. It is a method to fill the cavity of die casting mould with liquid or semi liquid metal under high pressure

at a high speed and solidify rapidly to obtain the casting. The mold used is called a die casting die mold.

Types of die casting molds

According to the use, it can be divided into structural parts and decorative parts.

According to the application situation, it can be divided into automobile die casting mould, 3C product die casting mould, toy die casting mould, etc.

According to the characteristics of shape and wall thickness, it can also be divided into thin-walled die-casting mould, box die-casting mould and disc die-casting mould

Die casting machine, die-casting alloy and die-casting die are the three elements of die-casting production, one of which is indispensable.

The type of die-casting machine, die structural parameters, die-casting process and factory layout depend on the die-casting alloy material, so the classification of die-casting die according to alloy material is most suitable for production practice. they are die-casting mold can be divided into aluminum alloy die-casting mold, zinc alloy die-casting mold, magnesium alloy die-casting mold and copper alloy die-casting mold. The details are as follows:

1).Aluminum die casting mold

2).Zinc die casting mold

3).Magnesium alloy die-casting mold

4).Copper alloy die-casting mold

5).Sintering mold

Aluminum die casting mold

Zinc die casting mold

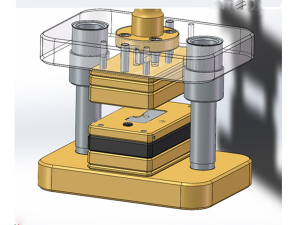

Die casting mold composition

The composition of die casting mold can be roughly divided into two parts:

Stationary mold half:To be fixed on the fixed mold mounting plate of the die casting machine, with a sprue connected with a nozzle or a pressure chamber;

Movable mold half:To be fixed on the mounting plate of the die-casting machine, and moved with the mounting plate to open and close the mold. When closing the mold, the mold cavity and the casting system are created, and the liquid metal fills the mold cavity under high pressure. When opening the mold, the movable mold half and the stationary mold halt are separated, and the casting is pushed out with the help of the ejection mechanism set on the movable mold half.

The die-casting die structure includes the following sub-systems according to its functions:

1) Cavity: surface sprue (sprue sleeve); Core: inner gate of inner surface.

2) Guide parts: guide post; guide sleeve.

3) Launch mechanism Push rod (thimble), reset rod, push rod fixing plate, push plate, push plate guide post, push plate guide sleeve.

4) Side core pulling mechanism Boss, hole (side), wedge block, limit spring, screw.

5) Overflow system Overflow trough, exhaust trough.

6) Supporting parts.

Stationary mold base plate, movable mold base plate, cushion block (assembly, positioning, installation function).

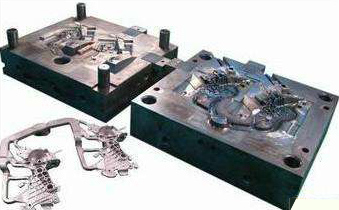

The difference between die casting mold and plastic mold:

1. The injection pressure of die casting die is large. Therefore, the template should be relatively thick. Prevent deformation.

2. The gate of die casting mold is different from that of injection mold. High pressure of the material flow to be decomposed by the splitter cone .

3. The core of die casting die does not need to be hardened. Because the temperature in the die cavity is over 700 ℃. Therefore, each molding is equivalent to one quenching. The cavity will get harder and harder. The general injection mold should be quenched to above hrc52.

4. Generally, the cavity of die-casting die needs nitriding treatment. Prevent the alloy from sticking to the mold cavity.

5. Generally, the corrosion of die casting die is relatively large. The outer surface is generally bluish.

6. Compared with injection mold. The fit clearance of the movable part of the die casting die (such as the core pulling slider) should be larger. Because the high temperature of die casting process will cause thermal expansion. If the clearance is too small, the mold will be stuck.

7. The parting surface of die-casting die has higher matching requirements. Because the fluidity of alloy is much better than that of plastic, it is very dangerous for high temperature and high pressure material flow to fly out of parting surface.

8. Injection mold usually relies on thimble. The parting surface can be vented. The die-casting mould must be provided with an exhaust slot and a slag collecting bag (to collect the cold material head).

9. Forming is inconsistent. The injection speed of die casting molding is fast. First stage injection pressure. Plastic mold is usually divided into several injection, pressure.

10. The die-casting mold is two plate mold (I haven't seen three plate die-casting mold at present) one opening. Different product structures of plastic moulds are different. 3 plate moulds are common. The number and sequence of opening are matched with the die structure. Square thimble is not usually used in die casting mold. Cylinder.

11. Inclined pin (high temperature and good solution fluidity) is easy to jam, which leads to unstable mold production. In addition, plastic mold and die-casting mold are made of different steel; plastic mold generally uses 45 × steel, T8, T10 and other steel, while die-casting

Mestech company focuses on the field of precision mold manufacturing and parts production for more than 10 years, with advanced industry technology and rich mold production experience. The company's products are mainly plastic products or shell materials such as electronic digital products, medical devices, infant products, etc., as well as plastic products such as household products and auto parts. The company has strong ability of structural design and mold design, which can provide customers with more optimized suggestions on product structure and more reasonable plans for mold