Metal prototype

Short Description:

Metal prototype is always made for engineers to verify the design of device or machine. Mestech provides metal prototype manufacturing of customers.

Metal prototype is always made for engineers to verify the design of device or machine. Mestech provides metal prototype manufacturing of customers.

Metal parts are often used to make precision parts and equipment shells, and they are more expensive than those of plastic parts. In order to improve the design and reduce the risk, it is necessary to make prototype samples for design and process verification before formal production.

Metal parts are widely used in various machinery and equipment. They are usually used to make precision parts because of their dimensional stability, strength and hardness, high and low temperature characteristics and electrical conductivity, which are far superior to plastic parts.

Compared with plastic parts, there are many kinds of materials for metal parts, such as aluminium alloy, copper alloy, zinc alloy, steel, titanium alloy, magnesium alloy and so on, with different properties. Among them, ferroalloys, aluminum alloys, copper alloys and zinc alloys are most commonly used in industrial and civil products. These metal materials have different physical and chemical properties, and the processing technology of metal parts with different structures and shapes is quite different.

According to the material and the structure of the parts, there are many kinds of mass production forming processes for metal parts, such as cutting, die casting, blanking, calendering, bending, extrusion and sintering. For the die-casting, blanking, extrusion and sintering, the molds are used. A mold usually means high expense investment, so mechanical cutting is generally used for their prototype making.

There are three main process to make metal prototype sample :

1. Machining.

Mainly used for parts with high dimensional accuracy and small parts.

The main equipment is CNC milling machine, lathe, grinder, EDM, WEDM and other machine tools.

For the processing of plane, surface, groove and hole of axle, sleeve, disk, cuboid and curved surface metal parts.

Special precision machine tools are used to process parts with high precision requirements. Parts such as gears, screw rods, etc.

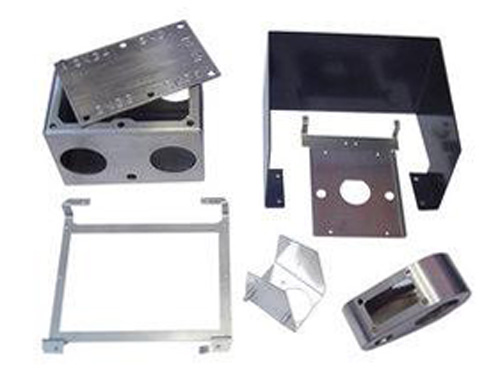

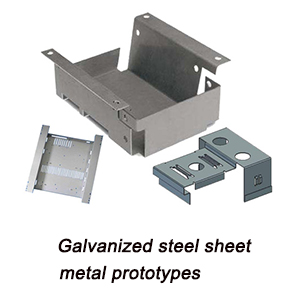

2. Sheet metal processing

For the shell and cover samples with thin wall and the same thickness everywhere, sheet metal process is generally used, that is, by means of laser cutting machine and some simple fixtures or tools through bending, cutting, stamping and hammering. It mainly depends on manual production.

For example, car housing, computer chassis, etc.

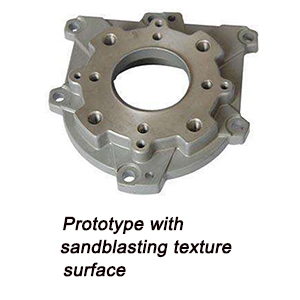

3. Surface Post-treatment

After machining or sheet metal processing, the basic design dimensions and shapes are obtained. In order to obtain good surface quality and appearance, surface treatment is often required.

A. Surface finishing: grinding, polishing, texturing, laser carving and embossing.

B. Powder spraying, electroplating, oxidation and painting.

Aluminum CNC machining prototypes

Precision machined steel prototype

Stainless steel sheet prototypes

The high hardness, high melting temperature points characteristics and high precision requirements of metal materials determine their processing technology different from that of non-metallic material (such as plastics) in making prototypes or samples. Our company provides customers with a full range of one-stop prototype or mockup manufacturing and service, including plastic parts, silica gel parts, metal parts and so on. If you need it, please contact us.