Mold (mould) and die are tools to make the blank or raw material into parts with specific shape and size under the action of external force. This tool is composed of various parts, and different molds are composed of different parts. It is the processing that mainly change the physical state of the material to achieve the shape of the object . Mold and die are tools for mass production. The application of mold greatly improves the production efficiency and repetitive manufacturing accuracy of parts. It is known as the "mother of industry".

Mold and die can be divided into two categories according to their processing characteristics

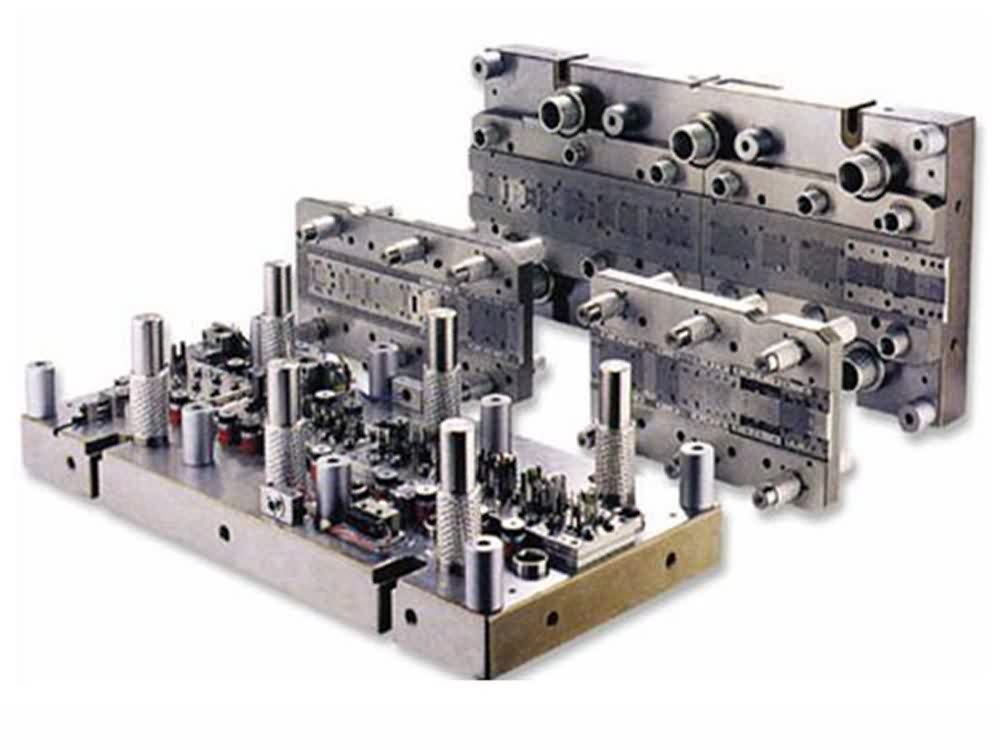

1. Die: the application of edge shape can make the solid blank separation (blanking) according to the contour shape, or bending extrusion molding. This kind of die is used for blanking, die forging, cold heading and extrusion of parts.

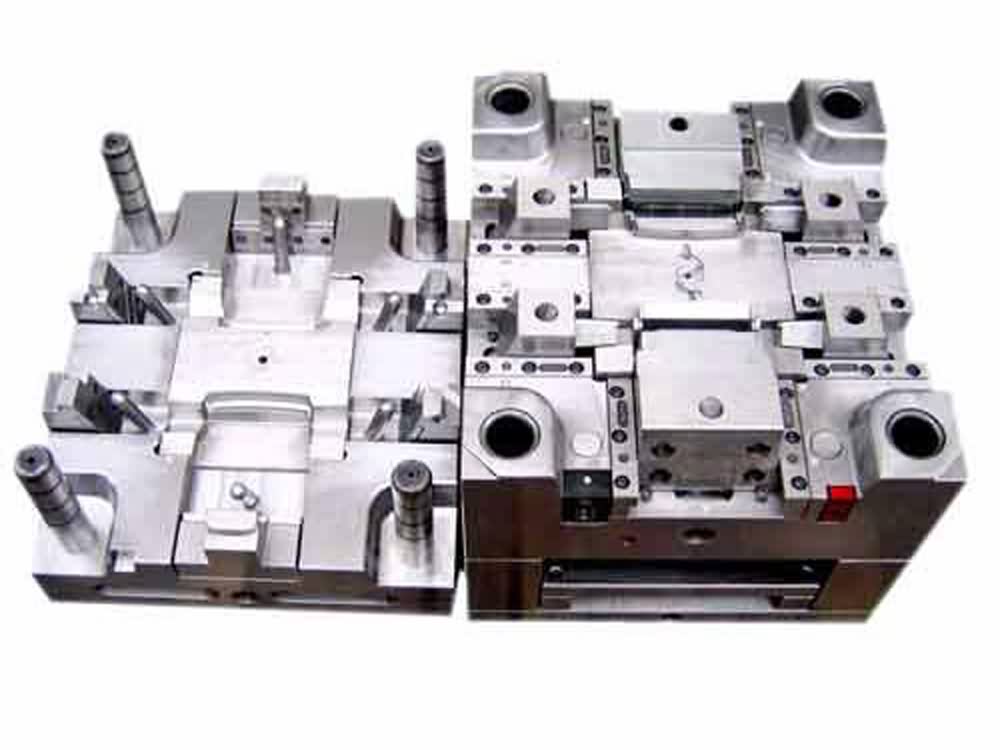

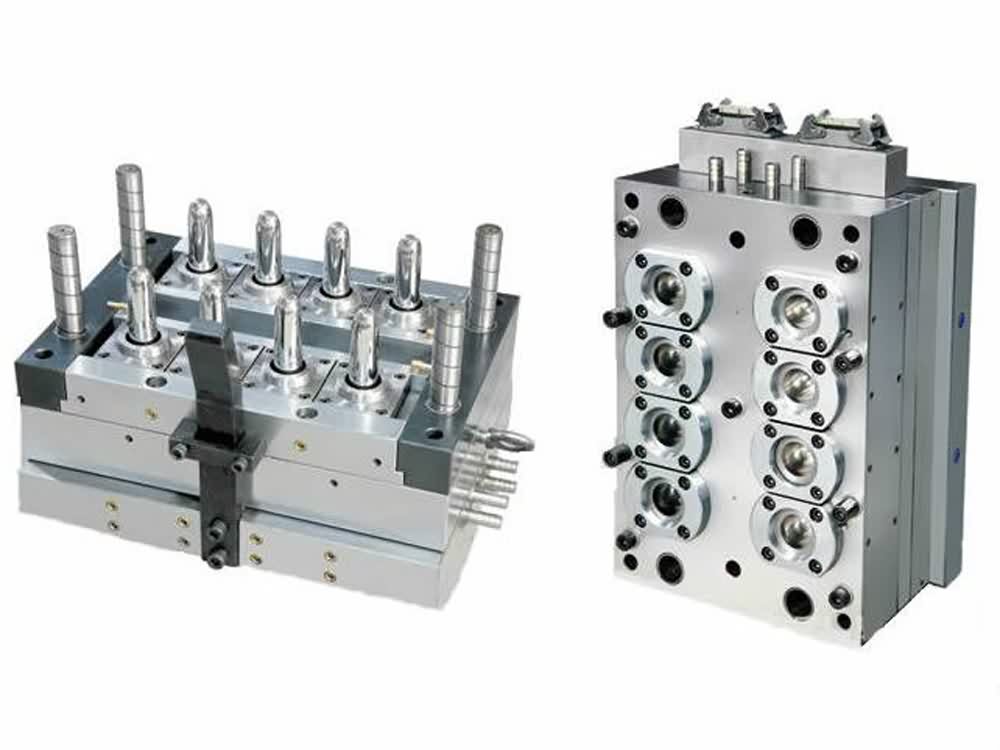

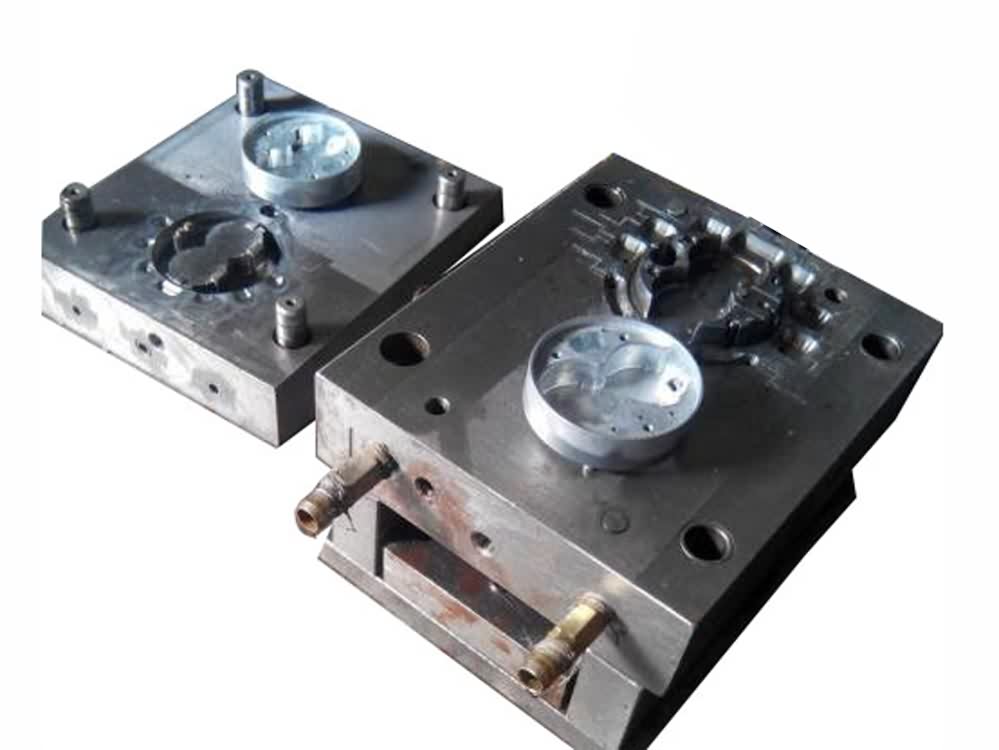

2. Mold: colloidal or liquid materials are injected into the mold cavity, or solid materials are melted in the mold cavity, filled and cooled to obtain products with the same shape as the mold cavity. This kind of mold is used in plastic parts injection molding, silica gel molding, metal die casting. Generally out of habit, we classify dies for non-ferrous metals such as aluminum alloy and zinc alloy as die

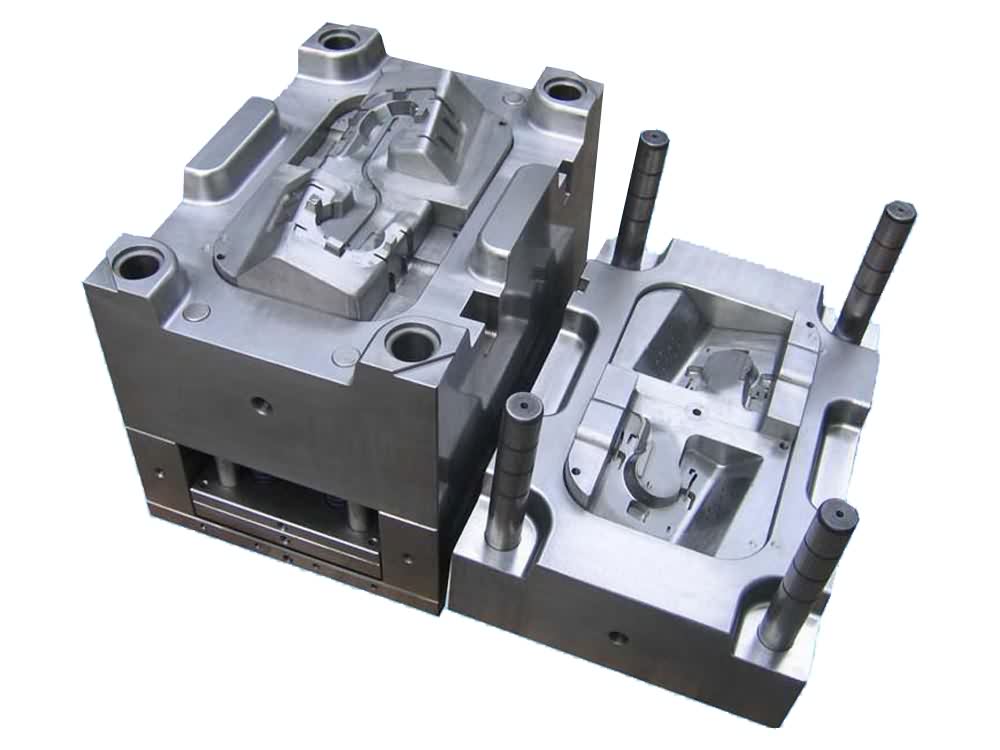

Plastic injection molds

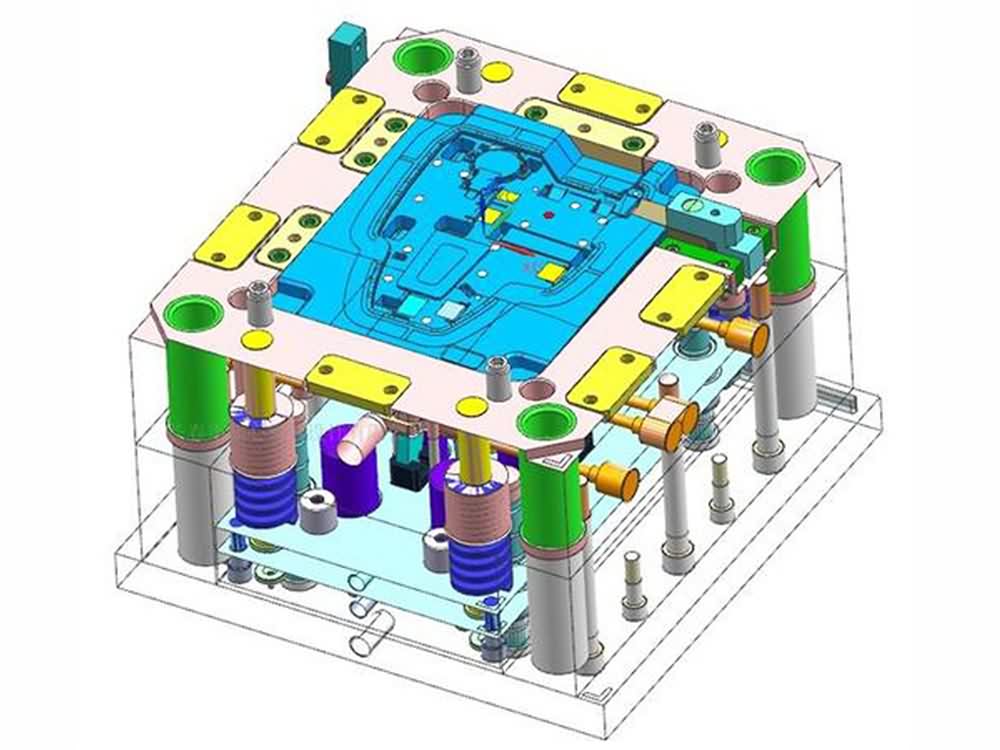

Mold design

Hot runner mold

Insert molding

Double injection molding

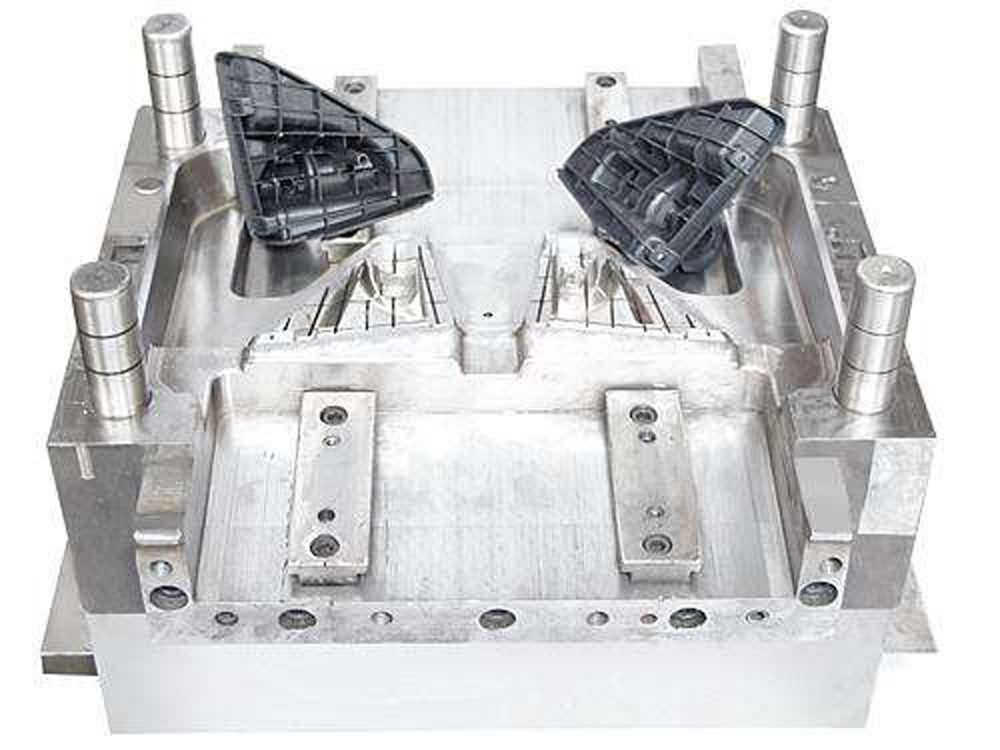

Injection mold for automobile parts

Silicone molds

Die casting molds

Metal stamping molds

HASCO injection molds

According to materials of the products produced through mold, the mold is divided into:

metal mold, plastic mold, and pecial mold.

1.Metal mold: including stamping die (such as blanking die, bending die, drawing die, flanging die, shrinkage die, undulating die, bulging die, shaping die, etc.), forging die (such as die forging die, upsetting die, etc.), extrusion die, die casting die, forging die, etc;

2.Nonmetal mold is divided into: plastic mold, inorganic non-metallic mold, sand mold, vacuum mold and paraffin mold. Among them, with the rapid development of polymer plastics, plastic mold is closely related to people's life. Plastic mold can be generally divided into: injection molding mold, extrusion molding mold, gas assisted molding mold, etc

The mold and die has a specific contour or cavity shape, and the blank can be separated (blanking) according to the contour shape by using the contour shape with edge. By using the shape of the inner cavity, the blank can obtain the corresponding three-dimensional shape. The die generally includes two parts: moving die and fixed die (or punch and die), which can be separated and closed. The parts are taken out when they are separated, and the blank is injected into the die cavity for forming when they are closed.

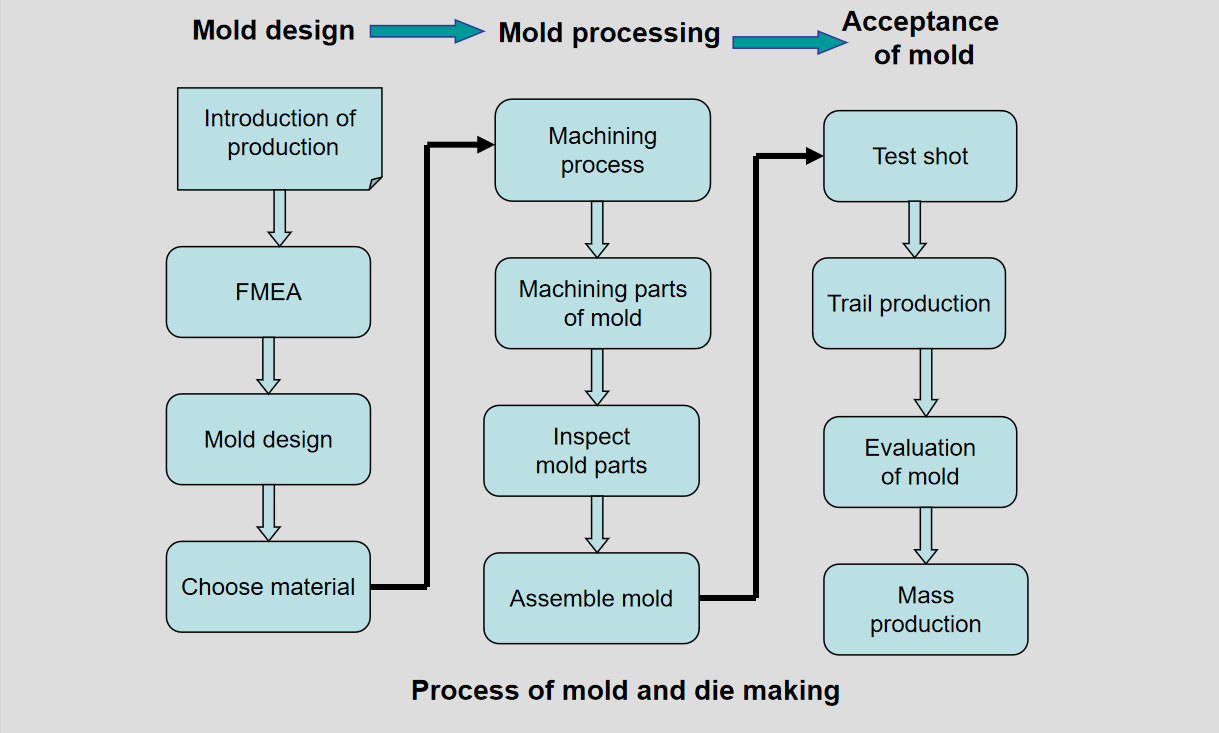

There are three stages in the production of mould : 1.Mold design ; 2.mold processing; 3.Acceptance of mold

Mestech provides customers with the design of plastic parts and metal parts, the manufacture of injection mold, die casting mold and blanking mold. And the use of molds for mass production of plastic parts, metal parts. We are looking forward to working with you to provide you with mold manufacturing and plastic, metal parts production and services.