Mould classification

Short Description:

Mould(mold, die) is a very big family, it plays an important role in modern industry. A clear mold classification is very important for understanding industrial production.

Mold (mould, die) is a special tool used in human activities. Mold classification includes a wide range. In modern society, old is closely related to industrial manufacturing, which greatly improves the production efficiency and precision of parts.

Mold is a special tool used in human activities. Mold classification includes a wide range. In modern society, mold is closely related to industrial manufacturing, which greatly improves the production efficiency and precision of parts.

Mold is the technological equipment that shapes (shapes) materials into products and parts with specific shapes and sizes. Including: stamping die, plastic injection mold, die casting mold, forging mold, powder metallurgy die mold, drawing die, extrusion die, rolling die, glass die, rubber mold, ceramic mold, casting mold and other types. In modern industry, the mold mainly refers to the mold used in the mass production of plastic parts and hardware parts. When it is used to form a solid object from the liquid plastic, metal and other materials injected into its cavity, we call it a “mold” or "mould". When it is used for punching, bending, bending and extrusion of solid blank, we generally call it a "die" .

The mold are classified by its features as follows:

Classification by materials and processing technology, the molds can be divided into hardware die mold, plastic mold and special mold.

(1) Non-metallic and powder metallurgical moulds: plastic moulds, sintering moulds, sand moulds, vacuum moulds and paraffin moulds.

With the rapid development of polymer plastics, plastic moulds are closely related to people's lives. Plastic moulds can be generally divided into: injection moulds, extrusion moulds, gas-assisted moulds, etc

(2) Hardware dies are divided into:die casting die, stamping dies (such as punching dies, bending dies, drawing dies, turning dies, shrinkage dies, undulating dies, bulging dies, shaping dies, etc.), forging dies (such as die forging dies, upsetting dies, etc.), extrusion dies, die casting dies, forging dies, etc.

Metal stamping die

1.Classification of plastic moulds

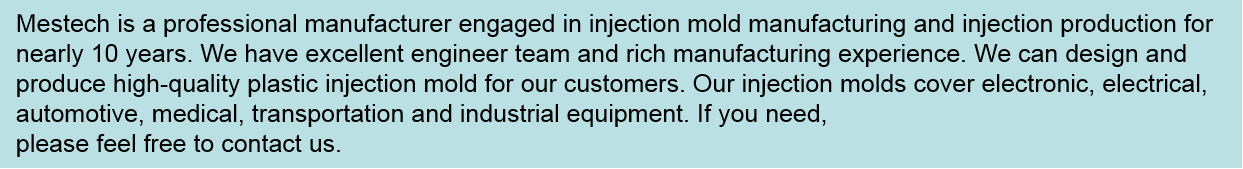

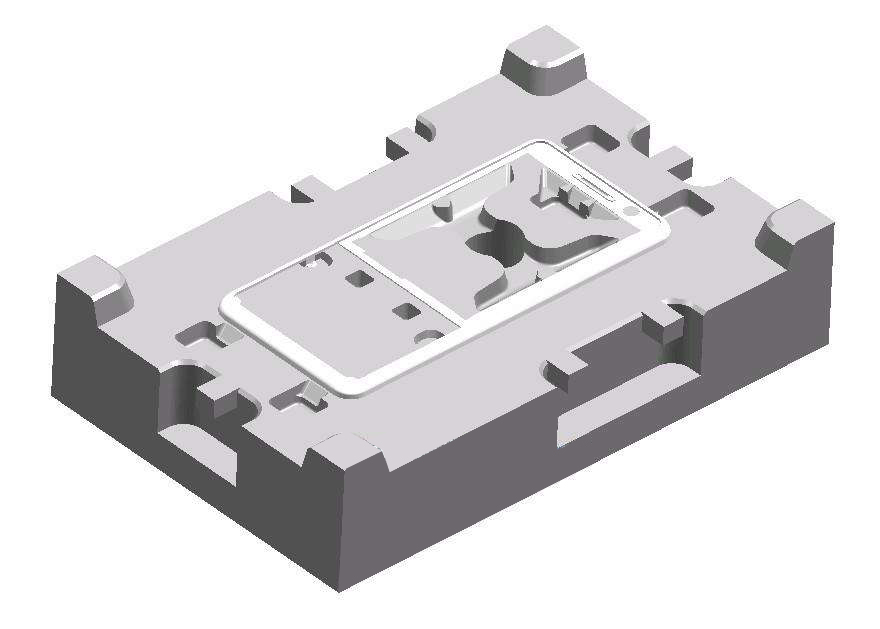

(1) Injection Mold

Injection mold is a kind of mold used for forming parts of thermoplastic and thermosetting plastics. Injection molding is widely used because of its high precision and efficiency. Injection molding is to add the plastic into the heating barrel of the injection machine. The plastic is heated and melted. Driven by the screw or plunger of the injection machine, the plastics injected into the mold cavity through the nozzle and the mold pouring system, and hardens and shapes into the injection products due to the physical and chemical actions. Injection moulding is a cycle consisting of injection, holding pressure (cooling) and demoulding process of plastic parts.Therefore, injection moulding has periodic characteristics.

Thermoplastic injection molding has the advantages of short molding cycle, high production efficiency, small wear of molten materials on the mold, and large batch of plastic parts with complex shape, clear surface pattern and mark, and high dimensional accuracy. However, for plastic parts with large wall thickness change, it is difficult to avoid molding defects. Anisotropy of plastic parts is also one of the quality problems. All possible measures should be taken to minimize it.

Injection mold

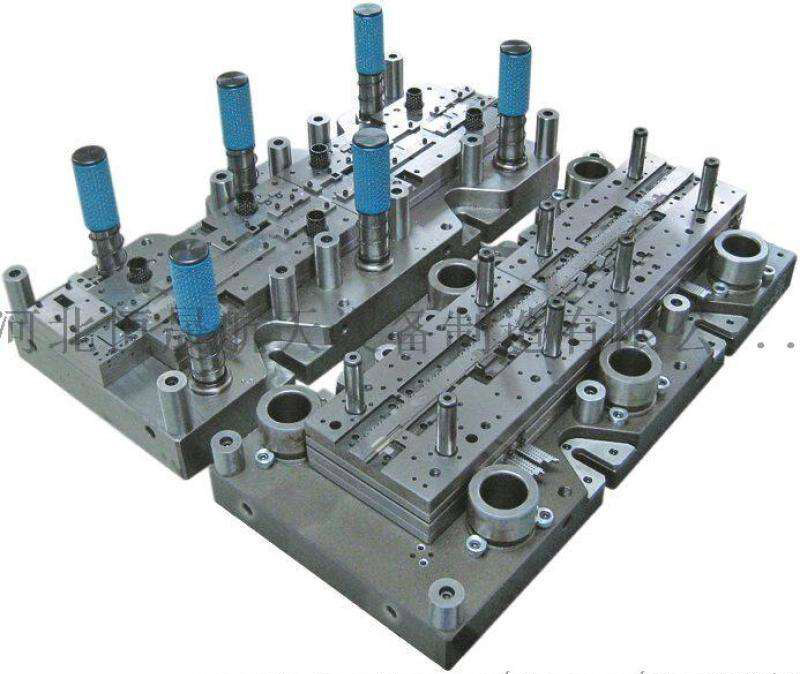

(2) Extrusion mold for plastic

Plastic extrusion molding is a kind of forming method to make the plastic in viscous flow state pass through the die with specific cross-section shape at high temperature and certain pressure, and then shape it into the continuous profile with required cross-section shape at lower temperature. The production process of extrusion moulding is preparation of moulding materials, extrusion moulding, cooling setting, traction and cutting, post-processing of extruded products (conditioning or heat treatment). In the process of extrusion, attention should be paid to adjusting the temperature, screw speed and traction speed of each heating section of the barrel and die of the extruder in order to obtain qualified extrusion profile.

Special attention should be paid to adjusting the extrusion rate of polymer melt from die. Because when the extrusion rate of molten material is low, the extrudate has smooth surface and uniform cross-section shape, but when the extrusion rate of molten material reaches a certain limit, the extrudate surface will become rough and lose luster, and shark skin, orange peel, shape distortion and other phenomena will appear. When the extrusion rate increases further, the surface of the extrudate will be distorted, and even branched and broken into melt fragments or cylinders. Therefore, the control of extrusion rate is very important.

Plastic extrusion production line

Extrusion die

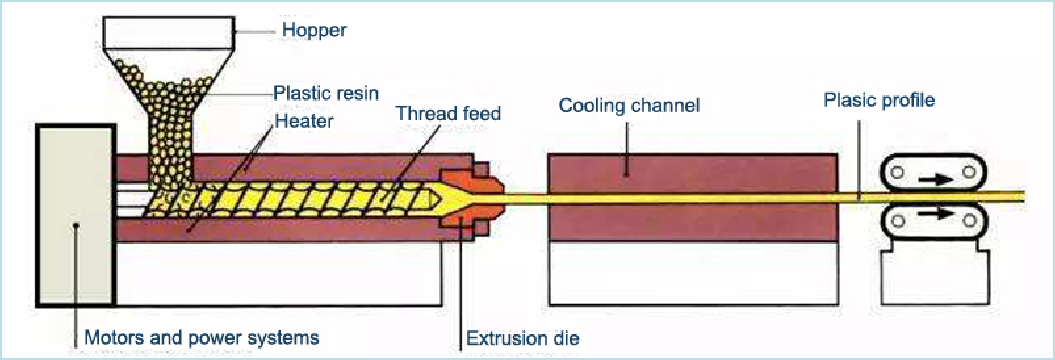

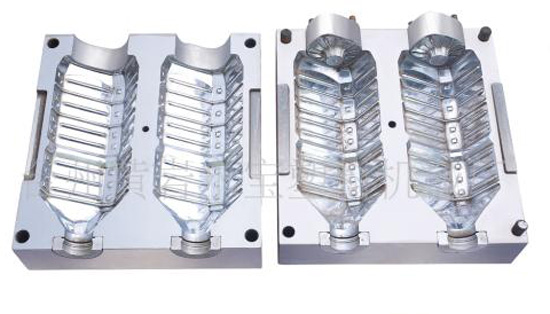

(3) Hollow forming mold

The hollow forming mold includes extrusion blow molding hollow forming and injection blow molding hollow forming two kinds of molds.

Hollow molding is a kind of processing method that fix the tubular or sheet blank which is made by extrusion or injection and still in the plasticizing state in the molding mold, immediately inject compressed air, force the blank to expand and stick on the wall of the mold cavity, and demould after cooling and finalizing, so as to obtain the required hollow products.

The plastics suitable for hollow moulding are high pressure polyethylene, low pressure polyethylene, rigid polyvinyl chloride, soft polyvinyl chloride, polystyrene, polypropylene, polycarbonate, etc. According to the different forming methods of parison, hollow forming can be divided into extrusion blow molding and injection blow molding. The advantage of extrusion blow moulding hollow forming is that the structure of extruder and extrusion blow moulds is simple. The disadvantage is that the wall thickness of parison is inconsistent, which easily causes the uneven wall thickness of plastic products. The right figure is the schematic diagram of the extrusion blow molding hollow forming principle.

Injection blow moulding has the advantage of uniform wall thickness and no flying edge. Because of the bottom of the injection moulding, the bottom of the hollow product will not produce splicing seam, which is not only beautiful but also high strength. The disadvantage is that the equipment and mould used are expensive, so this forming method is mostly used in the mass production of small hollow products, and it is not widely used in the use of extrusion blow molding hollow forming method.

Injection blow moulding for plastic

Blowing molds

(4) Die casting moulds for plastic

Die casting moulds are also called transfer moulds. The plastic material is added into the preheated feeding chamber, and then pressure is applied to the pressure column. The plastic melts under high temperature and pressure, and enters into the cavity through the casting system of the mould, gradually hardening and forming. This forming method is called die-casting forming, and the mould used is called die-casting moulding. This kind of mould is mostly used for thermosetting plastic forming.

(5) Compression Mold

Compression moulding is one of the earliest moulding methods of plastic parts. Compression forming is to add plastics directly into the open die cavity with a certain temperature, and then close the die. Under the action of heat and pressure, the plastic melts into a flow state. Due to physical and chemical action, plastics are hardened into plastic parts with certain shape and size at room temperature. Compression moulding is mainly used to moulding thermosetting plastics, such as phenolic moulding powder, urea formaldehyde and melamine formaldehyde moulding powder, glass fiber reinforced phenolic plastics, epoxy resin, DAP resin, silicone resin, polyimide and so on. It can also moulding and processing unsaturated polyester aggregates (DMC), sheet moulding plastics (SMC), prefabrication. Monolithic moulding plastics (BMC) etc. Generally, the matching structure of the upper and lower dies of the compression film is often pressed, and the compression dies are divided into three types: overflow type, non-overflow type and semi-overflow type.

(6) Pressure casting die

Also known as die casting. The plastic material is added into the preheated charging chamber, and then the pressing column is put into the charging chamber to lock the die. The pressure is applied to the plastic through the pressing column. The plastic melts into a flowing state at high temperature and high pressure, and solidifies into the cavity gradually through the pouring system. This forming method is also called transfer moulding. Pressure injection moulding is suitable for solid plastics with different melting points. In principle, it can be used for compression moulding or pressure injection moulding. However, when the solidification temperature is lower than the solidification temperature, the melting state has good fluidity, and when the solidification temperature is higher, the solidification rate is higher.

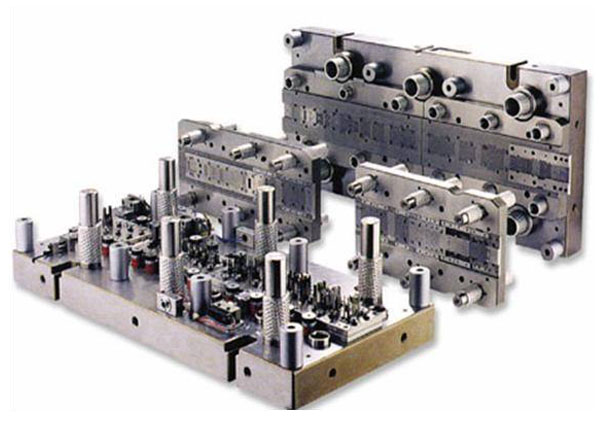

2. Classification of hardware dies

According to the equipment and process environment, metal mould can be divided into hot working mould and cold working mould. The difference between them is huge.

1) Hot working die: hot working die steel refers to the die suitable for hot deformation of metal, such as hot extrusion die, die casting die, hot forging die, hot upsetting die, etc. As the hot working die works under high temperature and high pressure for a long time, the die material is required to have high strength, hardness and thermal stability, especially high thermal strength, thermal fatigue, toughness and wear resistance. It mainly includes:

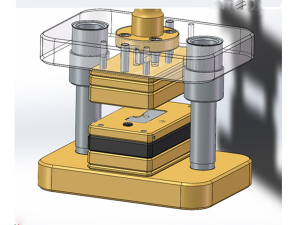

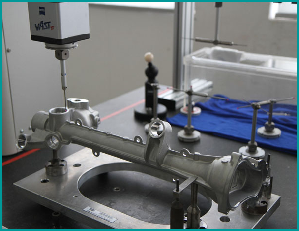

A. Metal die casting die mold: the process is to inject high-temperature molten liquid metal into the die cavity to obtain the required structural parts. Metal die casting is used to make complex shape parts of aluminum alloy, zinc alloy, magnesium alloy and other non-ferrous alloys.

B. Metal powder sintering mold: the process is to make metal powder into a certain shape and size of billet in the mold, and then heat the billet to the melting state, so that it can be formed. Metal powder sintering is mainly used for stainless steel, titanium, copper, iron, nickel and other high temperature alloy parts.

C. Metal hot extrusion die: hot working hot extrusion die is generally applicable to the processing of aluminum, magnesium, steel and other metals in high temperature environment, and the cross section shape of the generated parts remains unchanged. The hot extrusion die is required to have good heat-resistant wear resistance and tempering resistance.

Metal die casting mold

Hot extrusion die and aluminum profile

2) Cold working dies (Stamping dies): cold working dies are mostly dies working at room temperature, which are generally called stamping dies (such as punching dies, bending dies, drawing dies, turning dies, shrinkage dies, rolling dies, bulging dies, shaping dies, etc.). The working part of the cold working die generally needs to bear a lot of pressure, bending force, impact force and friction force, so the deformation resistance is relatively large.

A. Metal blanking die: the metal blanking die is used to cut two-dimensional shape from the metal plate. The parts can also be used as the blank for bending, drawing and forming. Blanking is mainly used for blanking, punching and trimming of steel, stainless steel, aluminum alloy, copper alloy and other plates.

B. Bending die: a part that uses a die to bend plates, bars and sections into a certain angle, curvature and shape. It is suitable for steel, stainless steel, aluminum alloy and copper alloy parts.

C. Drawing die: drawing is the process of stamping, drawing ring or metal die to transform sheet metal materials into cylinder or box shaped parts. Drawing die is a common tool for drawing.

D. Forming die: using die forming is a kind of production method that plastic deformation is carried out on solid while its quality and material characteristics remain unchanged. E. Riveting die: metal riveting is a method of connecting two workpieces through the middle workpieces by mechanical force. Generally, riveting is used between flat plates. The die used in the process is called riveting die.

Bending die

Metal stamping die

Application of molds or dies:

(1). Electronic and communication products;

(2). Office equipment;

(3). Automobile spare parts;

(4). Household appliances;

(5).Electrical equipment;

(6). Medical and environmental protection;

(7). Industrial facilities;

(8).Artificial intelligence;

(9). Transportation;

(10). Building materials, kitchen and toilet equipment and tools;