PC resin injection molding

Short Description:

PC resin (polycarbonate) injection molding parts are widely used in electrical products, electrical instrument shells and electronic products.

PC resin injection molding parts are widely used in electrical products, electrical instrument shells and electronic products.

What is PC resin ?

What is PC resin (polycarbonate) is commonly known as polycarbonate, because of its excellent mechanical properties, commonly known as bullet-proof glue. PC has the characteristics of high mechanical strength, wide temperature range, good electrical insulation performance (but the arc resistance is unchanged), good dimensional stability and transparency.

The original color of PC is colourless and transparent. Various transparent, translucent and opaque colors and light diffusion properties can be obtained by adding toner or master batch. This makes it easy to make lamp shades and other parts with various colors.PC also has many modified products, such as glass fiber, mineral filler, chemical flame retardant and other plastics.

PC has poor fluidity and high processing temperature, so the processing of many grades of modified materials requires special plasticized injection structure.

Various colors after adding toner or masterbatch

Original color of PC resin

The physical parameters of PC resin

Density: 1.18-1.22 g/cm^ 3 linear expansion rate: 3.8 *10 ^-5 cm/ C thermal deformation temperature: 135 C low temperature - 45 CPC(Polycarbonate) is colourless, transparent, heat-resistant, impact-resistant, flame-retardant BI grade, and has good mechanical properties in common use temperature. Compared with polymethyl methacrylate, polycarbonate has good impact resistance, high refractive index and good processing performance. It has UL94 V-2 flame retardancy without additives. The wear resistance of polycarbonate is poor. Some polycarbonate devices for wear-prone applications require special surface treatment.

What is PC resin Used For ?

PC material has high heat resistance, high strength, good toughness, impact resistance, flame retardant, wide use temperature range, non-toxicity, transparency of up to 90%, and good mechanical properties in common use temperature. High dimensional stability, shrinkage rate is very low, generally 0.1%~0.2%. Widely used in: electronic appliances, optical lighting, medical equipment, tableware, machinery and other products and equipment.

Transparent fruit plates

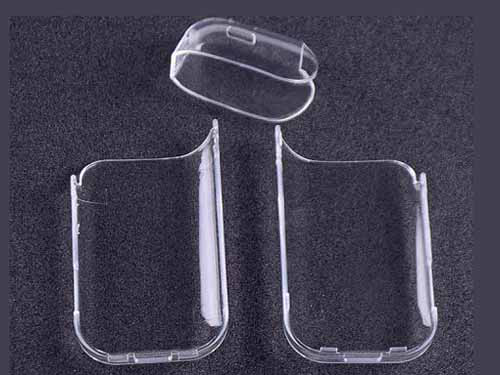

Transparent PC protective covers

Transparent & translucent PC lamp shades

Junction enclosure of PC resin

PC injection molding housing

PC lamp covers

What is the injection moulding process of PC resin material?

1. Plastics treatment

PC has a higher water absorption rate. It must be preheated and dried before processing. Pure PC is dried at 120 C. Modified PC is usually dried at 110 C for more than 4 hours. The drying time should not exceed 10 hours. In general, air-to-air extrusion method can be used to determine whether drying is sufficient.

The proportion of recycled materials can reach 20%. In some cases, 100% recycled material can be used, and the actual weight depends on the quality requirements of the product. Recycled materials can not mix different color masterbatches at the same time, otherwise the properties of finished products will be seriously damaged.

2. Selection of Injection Molding Machine

Because of cost and other reasons, PC products now use more modified materials, especially electrical products, but also need to increase fire resistance. In the process of forming flame-retardant PC and other plastic alloy products, the requirement of plasticizing system of injection moulding machine is good mixing and corrosion resistance. Conventional plasticizing screw is difficult to achieve. When choosing and purchasing, it must be certain. It should be explained in advance.

3. Design of Mould and Gate

Common mold temperature is 80-100 C, plus glass fiber is 100-130 C, small products can be used needle gate, gate depth should be 70% of the thickest part, other gates have ring and rectangular.

The bigger the gate, the better to reduce the defects caused by excessive shearing of plastics. The depth of the exhaust hole should be less than 0.03-0.06mm, and the runner should be as short and round as possible. The slope of demoulding is generally about 30'-1 degree

4. Melt temperature

The air injection method can be used to determine the processing temperature. Generally, the processing temperature of PC is 270-320 C, and some modified or low molecular weight PC is 230-270 C.

5. Injection speed

It is common to use a relatively fast injection speed to shape, such as switching on and off electrical appliances. Common is slow to rapid prototyping.

6, back pressure

The back pressure of about 10 bar can be reduced appropriately in the absence of airmarks and pornography.

7. Detention time

If the material stays at high temperature for too long, it will degrade, release CO2 and turn yellow. Do not clean barrel with LDPE, POM, ABS or PA. Use PS to clean up

PC resin is one of the four most commonly used plastic materials. Mestech has long used PC plastics and its alloys for injection moulding to produce various plastic parts. We are committed to serving customers with the moulding and injection moulding of this kind of products. If necessary, please contact us.