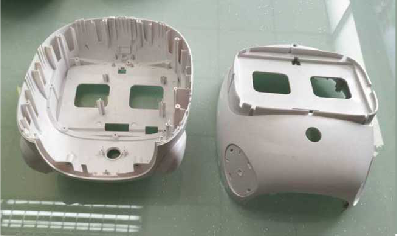

Plastic head shell for robot

Short Description:

Plastic head shell for robot: A front case and a rear case; Material ABS; Processing injection molding.

Mestech provides injection moulds and moulding parts for all kinds of robots for customers. Plastic parts such as head shell, joint, limb, etc.

Robots can take the place of or assist human beings to complete various tasks. Every dull, dangerous, poisonous and harmful work can be done by robots. Robots are widely used not only in manufacturing industry, but also in resource exploration and development, disaster relief and risk elimination, medical services, family entertainment, military and aerospace and other fields. Robot is not only an important production and service equipment in industry and non-industry, but also an indispensable automation equipment in advanced manufacturing technology.

Robots are generally made up of three elements: standby sensors, intelligent control systems and driving systems. With the development of artificial intelligence technology, in addition to industrial applications, intelligent robots are also entering the fields of office, family, service and education. People often give them human-like appearance, such as head, five senses, trunk, limbs, clothing and so on, to give people a better experience.

Following introduce the mould and injection production for plastic head shell for robot.

Product name: Plastic front case for robot

Mold standard (Customized) DME HASCO MISUMI China

Mold type: 2 Plate, mass production mold

Lead Time: 30-35workdays

Mold life: 300000-500000 Shots

Mold base: LKM

Mold cores' Material: S136H, 718H

Cavity: 1*1

Hardness: HRC42-50

Runner system: Cold runner system

Gate type: Open system

Material of product: ABS/PC

Sample submission time: within 3days after test shot

Injection machine: 200 tons

Injection production: China

Transport of goods: Sea/air

Design Software: UG,Proeng

Product name: Plastic rear case for robot

Mold standard (Customized) DME HASCO MISUMI China

Mold type: 2 Plate, mass production mold

Lead Time: 30-35workdays

Mold life: 300000-500000 Shots

Mold base: LKM

Mold cores‘ Material: S136H, 718H

Cavity: 1*1

Hardness: HRC50-52

Runner system: Cold runner system

Gate type: Open system

Material of product: ABS/PC

Sample submission time: within 3days after test shot

Injection machine: 200 tons

Injection production: China

Transport of goods: Sea/air

Design Software: UG,Proeng

Mestech produces plastic mold and injection molding for enclosure and head cover of AI equipment such as industrial robots and voice robots. If you need, please contact us.