Plastic injection molds

Short Description:

Plastic injection mold is the tool for producing plastic products, which is mainly used for mass production. Injection mold can provide complete structure and accurate size for plastic products conveniently and quickly .

What are plastic injection molds

Plastic injection mold (injection mould) is an kind of equipment to produce plastic products, and also a tool to give plastic products complete structure and accurate size. Injection molding is a kind of processing method used in mass production of some complex parts. Specifically, the plastic melted by heat is injected into the mold cavity by the injection molding machine under high pressure, and then cooled and solidified to obtain the molded products.

The Characteristics of injection mold

1.Injection mold can form plastic parts with complex structure, accurate size and good internal quality at the same time.

2.Although the structure of plastic mold may vary greatly due to the variety and performance of plastic, the shape and structure of plastic products and the type of injection machine, the basic structure is the same. The mold is mainly composed of pouring system, temperature regulating system, forming parts and structural parts. The pouring system and molding parts are the parts which are in direct contact with the plastics and change with the plastics and products. They are the most complex and changeable parts in the plastic mold, which require the highest processing finish and precision.

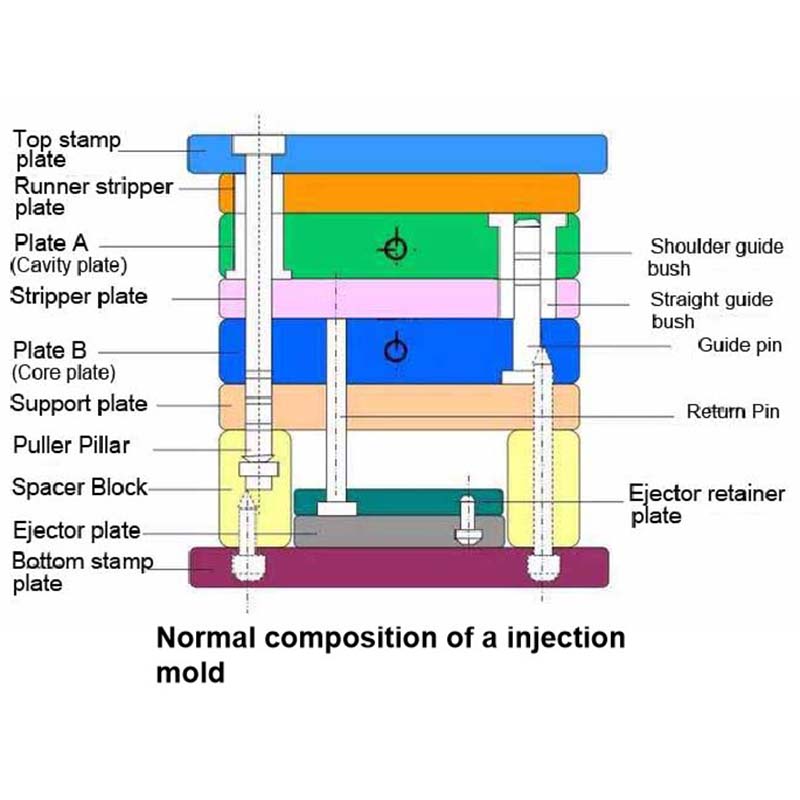

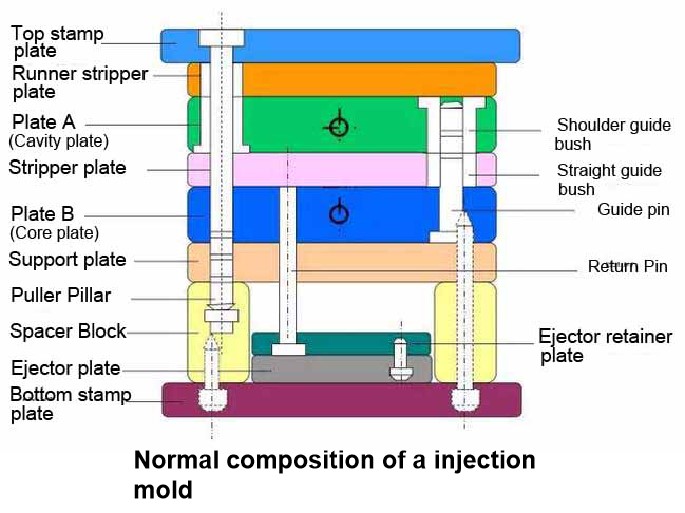

Composition of injection molds

The injection mold is composed of a moving mold and a fixed mold. The moving mold is installed on the moving template of the injection molding machine, and the fixed mold is installed on the fixed template of the injection molding machine. During the injection molding, the movable mold and the fixed mold are closed to form the pouring system and the mold cavity. When the mold is opened, the movable mold and the fixed mold are separated to take out the plastic products. In order to reduce the heavy workload of mold design and manufacturing, most injection molds use the standard mold base.

Types of molds according to use characteristics

(1) Hot runner molds

With the help of heating device, the plastics in the pouring system will not solidify and will not be demoulded with the product, so it is also called runnerless die. Advantages: 1) No waste 2) can reduce injection pressure, can use multi-cavity moulds 3) can shorten the moulding cycle 4) improve the quality of products suitable for hot runner moulding characteristics: 5) plastic melting temperature range is wide. It has good fluidity at low temperature and good thermal stability at high temperature. 6) It is sensitive to pressure and does not flow without pressure, but it can flow when pressure is applied. 7) Good specific heat, so as to cool quickly in the die. The plastics available for hot runners are PE, ABS, POM, PC, HIPS, PS. There are two kinds of common hot runners: 1) heating runner mode 2) adiabatic runner mode.

(2) Hard molds

The steel plate used in the inner die needs heat treatment after purchase, such as quenching and carburizing, to meet the requirements of use. Such injection mould is called hard die. For example, the inner die adopts H13 steel, 420 steel and S7 steel.

(3) Soft molds (below 44HRC)

The steel used in the inner mould can meet the requirements of use without heat treatment after purchase. Such injection is called soft mould. If the inner die is made of P20 steel, trump steel, 420 steel, NAK80, aluminum and beryllium copper.

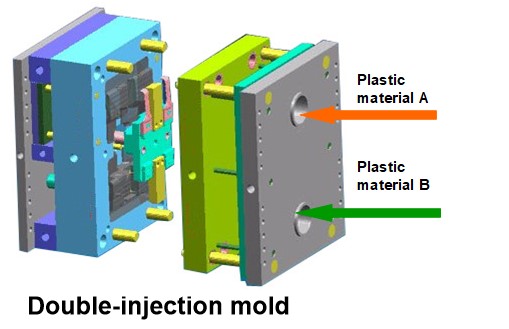

(4) Double-injection molds

A double-injection mold is a mold in which two plastic materials are injected on the same injection molding machine and molded twice, but the product is only ejected once. Generally, this molding process is also called two-component injection molding, which is usually completed by a set of molds and requires a special two-shot injection molding machine

(5) Injection molding with in-mold decoration & in-mold labeling

Plastic injection molds classification by gating system

Plastic moulds can be divided into three categories according to the different types of gating system.

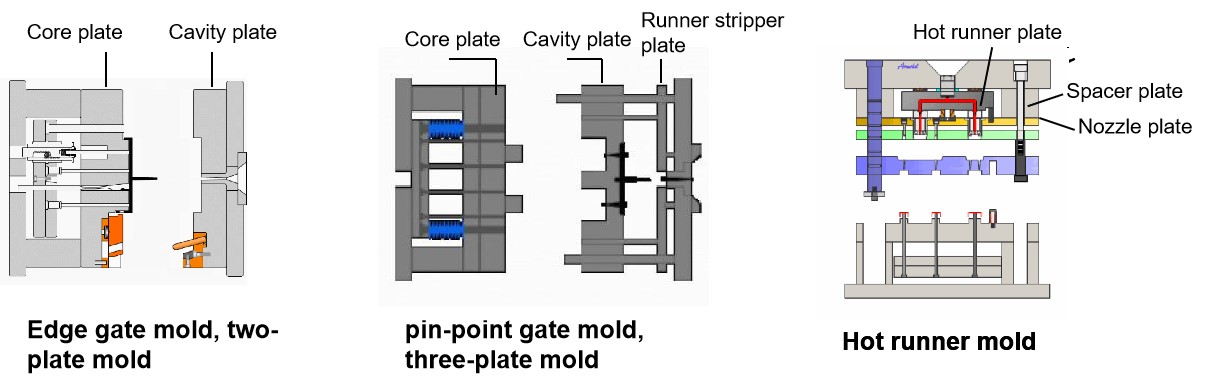

(1) Edge gate mold (two-plate mold): Runner and gate are demoulded together with the product on the parting line. The design is the simplest, easy to process, and the cost is low. Therefore, more people use large nozzle system to operate. The structure of plastic mould is divided into two parts: dynamic mould and fixed mould. The movable part of the injection machine is the movable part (mostly the ejection side), and the inactivity at the ejection end of the injection machine is generally called the fixing mold. Because the fixed part of the large nozzle die is usually composed of two steel plates, it is also called the two-plate mold. The two-plate mold is the simplest structure of the large nozzle mold.

(2) Pin-point gate mold (three-plate mold): the runner and gate are not on the parting line, generally directly on the product, so it is more complex to design a group of nozzle parting line, and difficult to process. Fine nozzle system is generally selected according to the product requirements. The fixed part of the fine nozzle molg is generally composed of three steel plates, so it is also called "three plate mold" for this kind of structural die. The three-plate mold is the simplest structure of the fine nozzle mold.

(3) Hot runner mold: The structure of this kind of die is basically the same as that of fine nozzle. The biggest difference is that the runner is located in one or more hot runner plates and hot suckers with constant temperature. There is no cold material demoulding and the runner and gate are directly on the product. Therefore, the runner does not need demoulding. This system is also called no nozzle system, which can save raw materials and is applicable. In the case of more expensive raw materials and higher requirements for products, it is difficult to design and process, and the cost of dies and moulds is high. Hot runner system, also known as hot runner system, mainly consists of hot runner sleeve, hot runner plate and temperature control electric box. Our common hot runner system has two forms: single-point hot runner and multi-point hot runner. Single point hot gate is to inject molten plastic directly into the cavity by a single hot gate sleeve, which is suitable for single cavity and single gate plastic mould; multi point hot gate is to divide the molten material into each branch Heat Gate sleeve by a hot gate plate and then enter into the cavity. It is suitable for single cavity, multi point feed and multi-cavity

The application of plastic injection molds

Injection mold is an important process equipment for the production of various industrial products. With the rapid development of plastic industry and the promotion and application of plastic products in the industrial sectors such as aviation, aerospace, electronics, machinery, ship and automobile, the requirements of the products on the mold are also higher and higher. The traditional mold design method has been unable to meet the requirements of today. Compared with the traditional mold design, computer-aided design CAE technology has great advantages in improving productivity, ensuring product quality, reducing cost and reducing labor intensity.

1. Electronic and communication products:

2. Office equipment;

3. Automobile spare parts;

4. Household appliances;

5.Electrical equipment;

6. Medical and environmental protection;

7. Industrial facilities;

8.Artificial intelligence;

9. Transportation;

10. Building materials, kitchen and toilet equipment and tools

Mestech is a professional manufacturer engaged in injection mold manufacturing and injection production for nearly 20 years. We have excellent engineer team and rich manufacturing experience. We can design and produce high-quality plastic injection mold for our customers. Our injection molds cover electronic, electrical, automotive, medical, transportation and industrial equipment. If you need, please feel free to contact us.