Plastic mold for laser hair removal machine

Short Description:

Mestech produces plastic molds and provide injection molding housing of laser hair removal machine for the customers.

Mestech produces plastic moulds for laser hair removal machine for the customers.

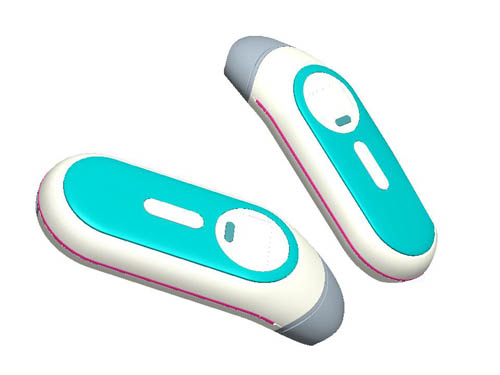

As a beauty cosmetics tool, laser hair removal machine is a popular product for young people.Such product requires beautiful appearance, suitable for young people's aesthetic habits.

Laser hair removal machine uses a specific wavelength of laser to act on the hair follicle, destroying the hair follicle so that hair no longer grows. Achieve the cosmetic effect of skin cleanliness.

Laser irradiation will cause the aging of the surrounding parts, and the laser will also generate heat, requiring the parts of the plastic housing to have anti-aging and heat-resistant performance. So the plastic mould of laser hair removal machine has its own characteristics.

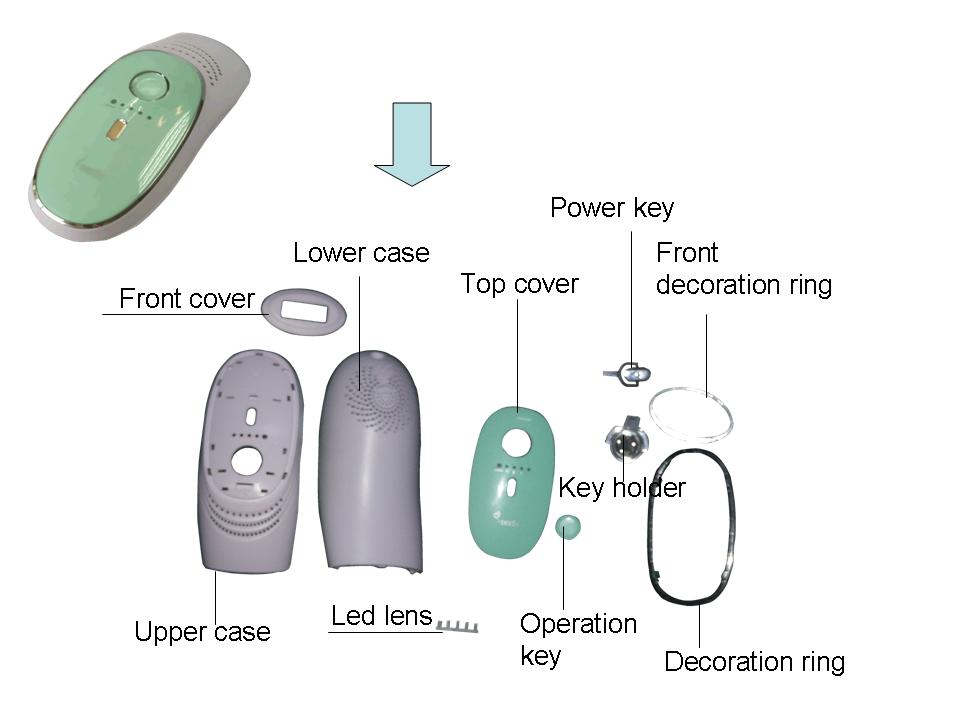

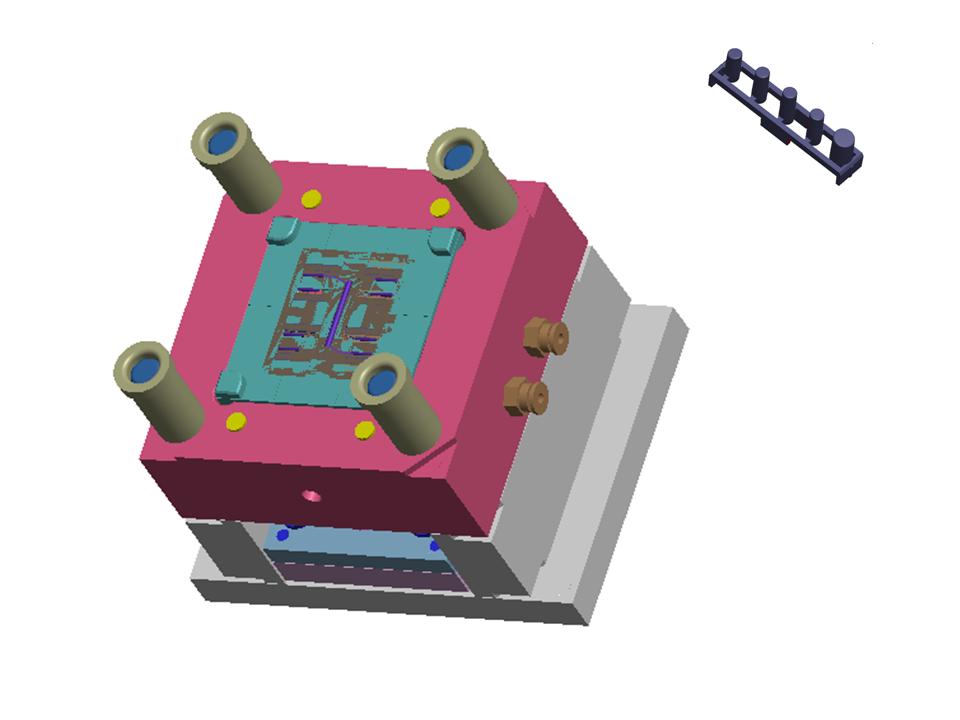

Laser hair removal machine is composed of laser generator and plastic housing, component fixing bracket and operation keys. Its structure is shown in the figure below.

---1. Upper case, lower case and front cover

---2. Top cover, operation key

---3. Decoration ring, power button. Key holder

---4. Led lens

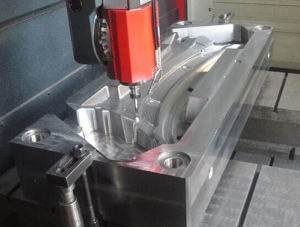

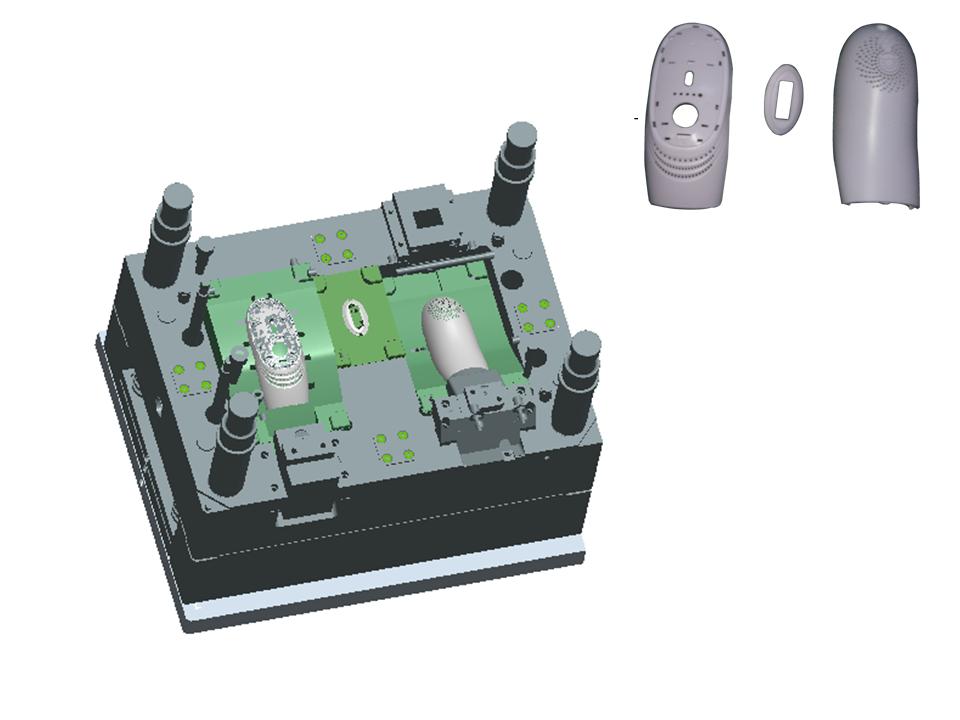

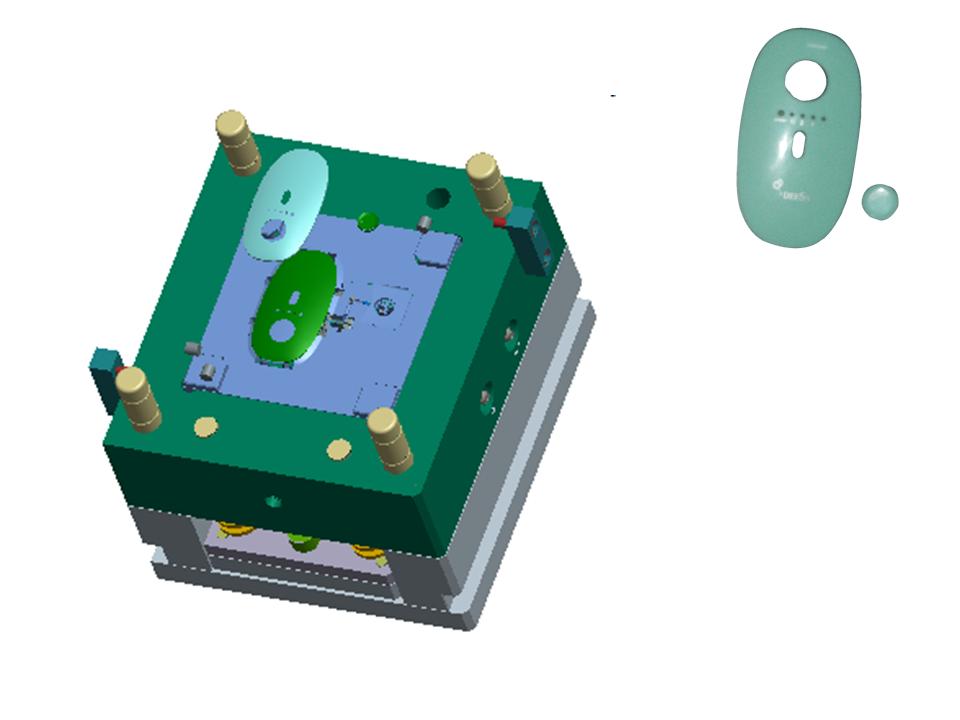

*Upper case, lower case , front cover and injection mold

1.Plastic resin: ABS/PC, ceramic white

2.Surface: fine texture

3.Cavity: 1+1+!

4. Material of mold: S136

5.Need time for mold making: 30days

*Top cover, operation key and injection mold

1.Plastic resin: ABS/PC, Pantone 563C

2.Surface: polished, silkscreen logo

3.Cavity: 1+!

4. Material of mold: S136

5.Need time for mold making: 27 days

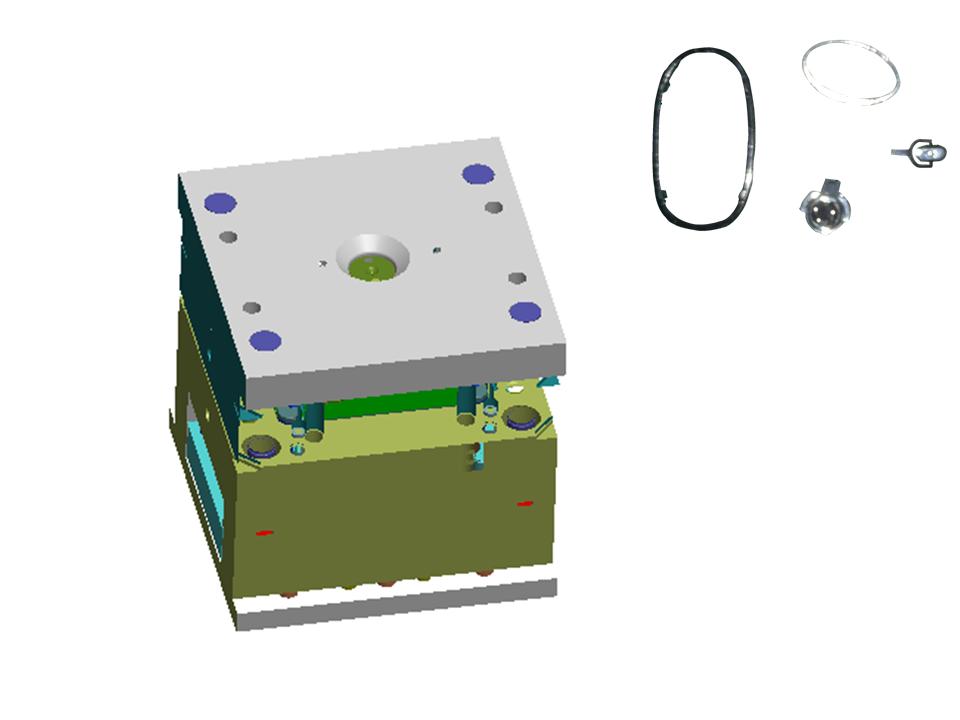

* Decoration ring, power button, key holder and injection mold

1.Plastic resin: ABS, original natural color

2.Surface: polished, high gloss chrome electroplated

3.Cavity: 1+!+1+1

4. Material of mold: S136

5.Need time for mold making: 27days

* Led lens and injection mold

1.Plastic resin: PC, milky translucent

2.Surface: texture code 20#

3.Cavity: 8

4. Material of mold: S136

5.Need time for mold making: 27days

The laser hair removal machine has a compact structure, and the positioning and fixing of the shell are completely connected by the plastic buckle, so there is a high demand for the accuracy of the mold, which is a precision mold. The surface treatment and decoration of each part are different. Some parts have fine lines, some parts are polished and some parts are electroplated. Different surface treatment processes bring different changes to the size and shape of parts. These factors must be considered carefully in mold design and manufacture.

Mestech company manufactures all kinds of plastic injection molds for beauty electronic products, and provides one-stop services such as parts injection molding, surface plating, painting, silk screen printing, etc. if you need, please contact us.