Plastic overmolding

Short Description:

Plastic overmolding is a special injection molding process, which is used to combine parts of two materials into one part through injection molding. The two parts were molded twice in different molds and injection molding machines.

Plastic over molding is a process to place one or more existing plastic parts of different material in to a injection mold before injection, then injection plastic into mold, the injected material cover or wrap the preplaced parts to form one single part.

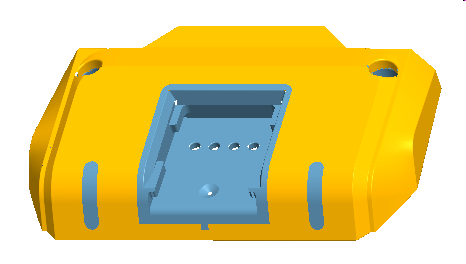

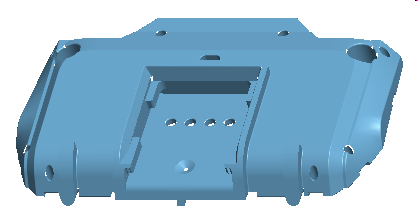

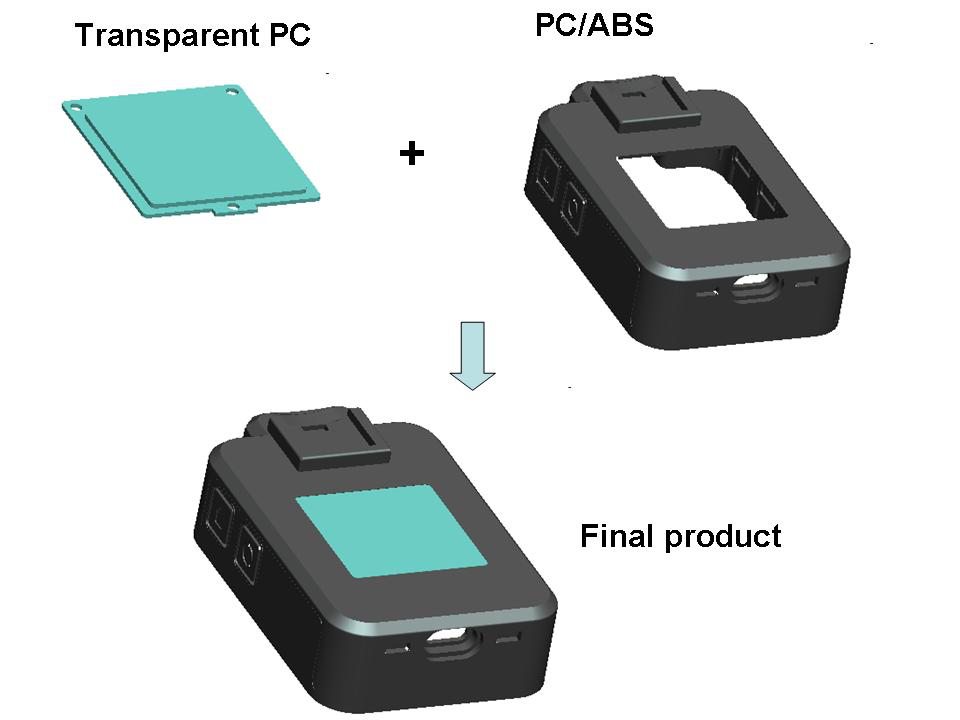

First step :prepare the pre-placed part .( mold1)

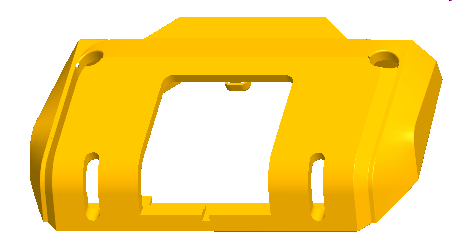

Second step: place the pre-placed in injection mold , and do over-molding with plastic resin.(mold2)

The final plastic part

There are two types of over molding

Type 1: The pre-placed parts/components are plastic, which were previously created in another mold. This method belongs to two-shot injection molding. This is plastic over molding we discussed here.

Type 2: The pre-placed parts are not plastic, but may be metal or other solid parts (e.g. electronic components). We call this process insert molding.

Usually pre-preplaced parts are partially or totally covered by subsequent materials (plastic materials) in the over-molding process.

Do you know the application of plastic over molding?

There are many purposes for plastic over molding. The most common among them are the following:

1. Add color to beautify the appearance (aesthetic impact).

2. Provide a convenient holding area on the part.

3. Adding flexible area to rigid parts to increase elasticity and touch feeling.

4. Add elastic material to cover product or seal for water-proof.

5. Save assembly time. There is no need to connect the metal part and the plastic part manually or automatically. You just need to put the hardware part into the mould and inject the plastic part. There is no need to assemble it at all.

5. Fix one part inside another without using fasteners or adhesives.

What kind of products is plastic over molding suitable for ?

The plastic over-molding process is suitable for many products, which vary according to the specific conditions of the products. Usually include toothbrushes, tool handles (such as cordless drills and screwdrivers) and personal care products (such as shampoo bottles and shavers), wire terminals, plugs, SIM holders, etc.

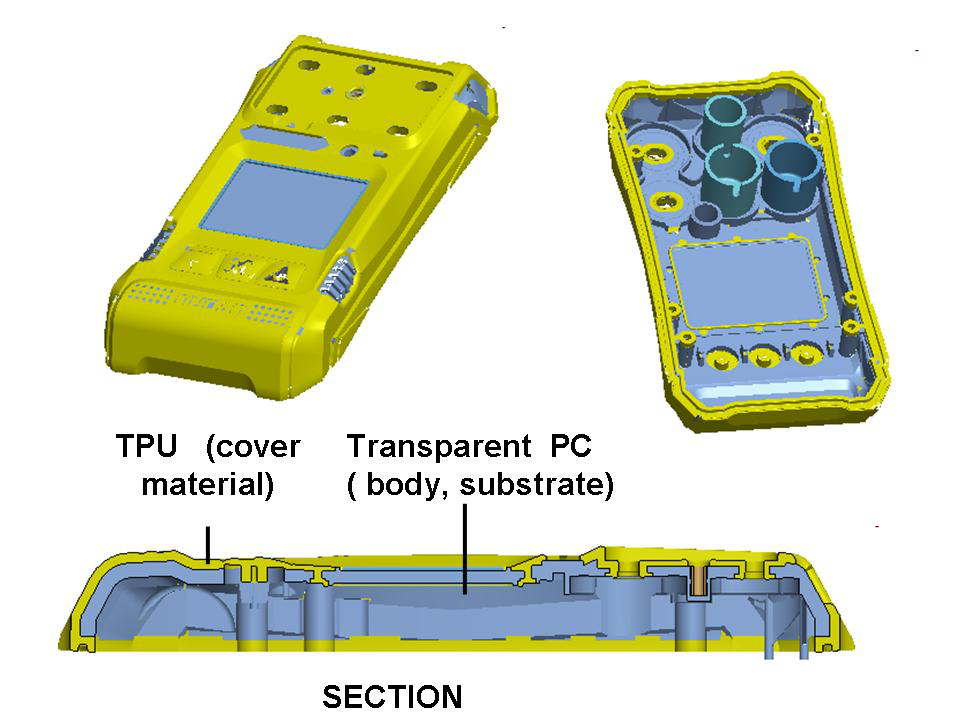

PC & TPU overmolding waterproof case

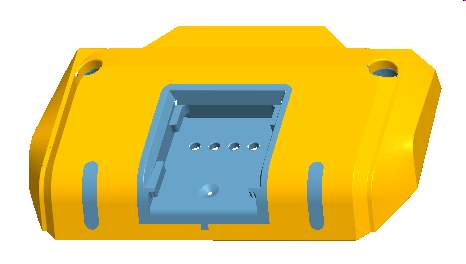

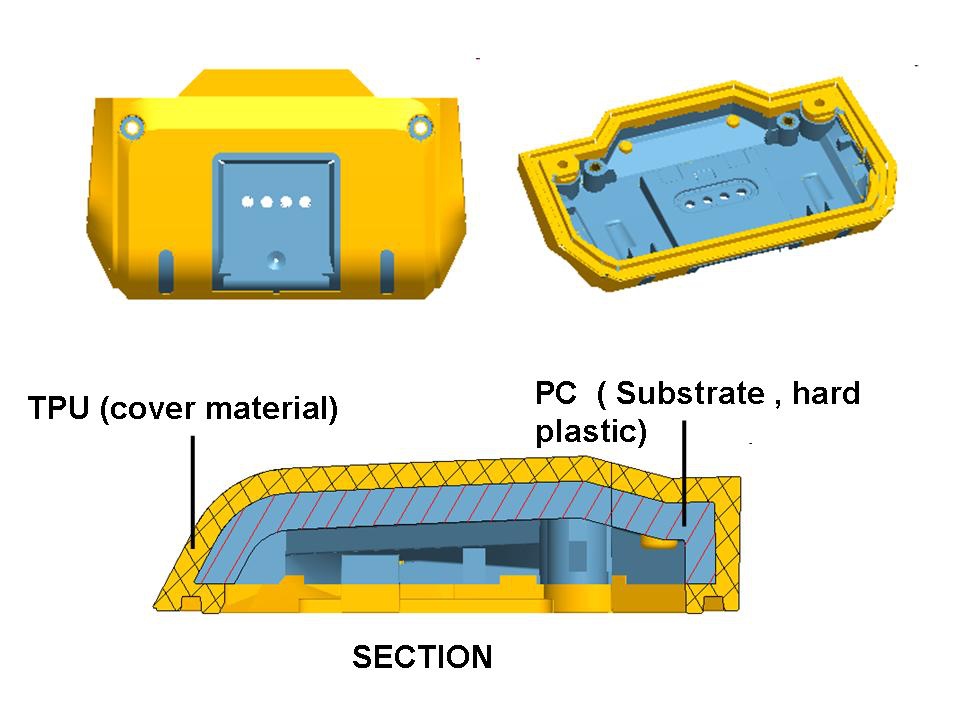

PC & TPU overmolding waterproof battery door

PC & PC/ABS overmolding plastic case for electronic product

PC & TPU overmolding protective case for mobilephone

Two color large size overmolding plastic part

ABS & TPE overmolding wheel

Here are some typical examples of over molding applications:

1. Hard plastic covering plastic - first of all, a rigid plastic pre-positioned part is formed. Then another hard plastic is injected onto or around the pre-positioned parts. Plastics may differ in color and/or resin.

2. Hard plastic wrapped in soft elastomer resin - first, rigid plastic parts are pre-placed. The elastomer resin ( TPU, TPE,TPR) is then moulded onto or around the pre-positioned parts. This is usually used to provide a soft hand-held area for rigid parts.

3. Plastic wrapped metal - first of all, the metal base is machined, cast or shaped. Then, the pre-placed parts are inserted into the injection mold cavity, and the plastic is molded into or around the metal. This is usually used to capture metal parts in plastic parts.

4.Elastomer resin covering Metal - First, the metal part is machined, cast or shaped. The pre-positioned metal parts are then inserted into the injection mold and the elastomer resin are injected onto or around the metal. This is usually used to provide a soft, well-gripped surface.

5. Soft elastomer resin wrap PCBA or electronic components, light-emitting module, etc

It is important to note that there are some limitations and compatibility problems between different materials that need to be considered for overmolding. You are not limited to two kinds of materials. We've seen some products, in a part with three different plastic resings combined to achieve a multi-color interwoven surface. Here's a simple example of a product you'll be very familiar with: scissors.

Usually, the pre-placed part materials or parts are placed in the injection moulds, at which time the overmolding plastic resins are injected into or around the pre-placed parts. When the encapsulated injection material is cooled and cured, the two materials are joined together to form an integral part. Additional tips: It's usually a good idea to have your pre-positioned parts and wrapping materials grasped mechanically. In this way, the two materials can be combined not only chemically, but also physically.

What is the advantage of over molding in production?

The over moulding mold has simple structure and flexible process.

1. It is applicable to the parts with large covering parts, especially the parts with inverted buckle. This kind of plastic parts are difficult to be injected in the same injection molding machine with two-color mold, which can be achieved by plastic covered injection molding.

2. When the shape of the plastic preset is simple and the size is very small, and the final part has a large size, it is suitable to adopt

plastic covered injection molding. At this time, the mold of the preset part mold can be made very small or multi cavity mold, which can greatly reduce the cost of the mold.

3. When the pre-placed parts and the encapsulated materials are all plastics (resins), it is suggested that the double injection moulding process should be used in mass production instead of overmoiding in order to obtain high quality, high productivity and low cost. When small batch production or quality requirements are not high, overmolding can be used to avoid the investment of the double-injection moulding machine and high cost of mould manufacturing.

What the materials are the pre-placed parts made of ?

We call the parts that were first placed in the mould the pre-placed parts( or pre-positioned parts).

The pre-placed parts can be any solid parts, a machined metal part, a moulded plastic part, or even an existing product, such as a nut, screw, or electronic connector. These pre-placed parts will be combined with later-injected plastics to form a single part by chemical action and mechanical connection. The elastomer resins (TPU, TPE,TPR) are also plastics, but not suitable for being pre-placed parts.

How to choose plastic resins for over molding?

The plastic resins used by over molding are usually plastics. They begin in the form of particles, and their melting point temperature is usually lower than that of pre-placed parts to prevent pre-placed parts from being damaged by high temperature. These particles are mixed with additives such as colorants, foaming agents and other fillers. Then it is heated to the melting point and injected into the mould as a liquid. There are some limitations on materials suitable for over moulding. If the pre-placed parts are metal parts, you can use any plastic as overmolding material. Compatibility problems may exist if the pre-placed part is made of another plastic resin (rubber or TPE) with low melting point.

Do you know the injection molding machine for over molding ?

The injection moulding machine used in plastic over-molding is a common injection moulding machine, which is divided into two types: vertical and horizontal.

1. Vertical injection moulding machine occupies more space than horizontal injection moulding machine of the same tonnage, which is not easy to maintain, so the tonnage is usually smaller. Particularly suitable for small size parts or pre-placed parts are not easy to be fixed in the molds.

2. Horizontal injection moulding machine has large tonnage and small occupancy space, which is suitable for molding large size parts.

How to choose the injection molding machine for over molding ?

1. Vertical injection moulding machine is usually used for small parts such as wire terminals and connectors, power plugs, lenses and so on. The moulds are simple and efficient.

2. Horizontal injection moulding machine is used for large size parts, which has sufficient power and is biased to operation.

3. Two-color injection moulding is recommended for pre-positioned parts and encapsulated materials, which can achieve better quality and productivity than encapsulated injection moulding.

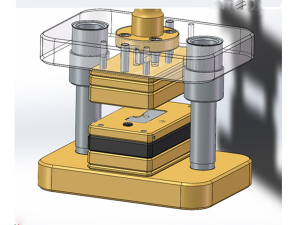

The injection molds for over molding

Overmolding usually has two sets of injection moulds. One is for the molding of the pre-placed part, another one is for over-molding final part.

When the pre-placed parts are non-plastic or no need injection molding, only one set of main moulds is needed. We call this process insert molding.

Mestech company has experience in plastic-clad injection moulding, especially in the plastic-clad injection molding of shells of various electronic and electrical products with hardware as preset parts. Mestech is also equipped with multiple double-color injection molding machines, which can produce various kinds of double-color plastic parts, plastic-coated parts of the mold and injection molding. If you need it, please contact us.