Prototype making is to make one or several samples according to the product's design drawing or conception, through some special processing methods, according to the requirements of product appearance and structure drawing without production mold.

The prototype is almost the same as the actual product in shape, color and shape. It is used to verify whether the size space combination features, appearance, color features and some functional features of the newly designed products are accurate and reasonable, or to show products to customers to obtain customers' opinions or market recognition.

Product life cycle starts from design and ends in market. Product design defines the function, appearance and reliability of products. Determine the process and cost of the product. Product design is a rigorous work, which is related to the success of the whole product. From product design to final mass production, any kind of product intended for mass production needs to invest a lot of money, time and energy. Good design is the key to product success. The production of product prototype to analyze, verify and improve product design is an important means to obtain perfect product design. Hand board manufacturing can effectively improve the speed of product development

General industrial products, such as electronics, electrical appliances, automobiles and medical devices, are made of plastic, hardware or electronic components. In order to avoid the serious waste in mass production mold and production caused by design errors, we make model samples at a small cost through machining, laser forming and temporary mold and other means for analysis, assembly and evaluation, or show them to customers.

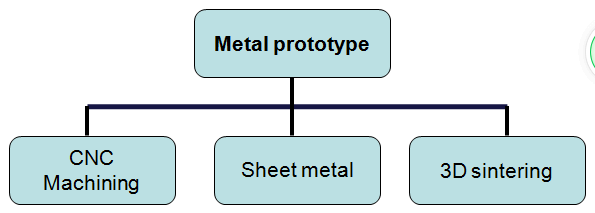

1. Manual production of metal model: there are three main ways to make metal part model

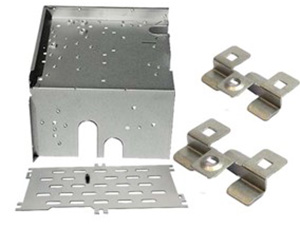

(1) . Sheet metal: bending, cutting, extruding and beating with hand or simple tools. This method is mainly used for the model making of thin-walled sheet metal parts. Applicable materials include steel, aluminum alloy, copper alloy and zinc alloy.

(2) CNC machining: milling, turning, grinding, discharging and drilling of metal materials on machine tools. This method is used for the manufacture of block and shaft parts models, sometimes the holes or local finishing of sheet metal models also need to be machined. Applicable materials include steel, aluminum alloy, copper alloy and zinc alloy.

(3) . Metal laser 3D printing (sintering): Metal 3D printing is used to produce parts with complex shapes and structures that are difficult to be produced by machining and sheet metal processing, such as engine blades, mold cooling water pipes, etc. Applicable materials include tool steel and martensitic steel, stainless steel pure titanium and titanium alloy, aluminum alloy, nickel base alloy, cobalt chromium alloy and copper base alloy

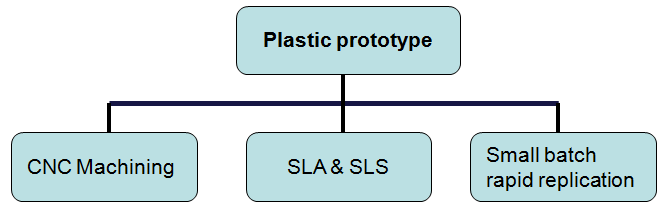

2. Plastic prototypes: there are three main ways to make plastic prototypes:

(1).CNC machining: that is, the plastic blank is machined on the machine tool. This method is used for machining shell, block and revolving body. Applicable to almost all hard plastic materials.

(2). Laser 3D printing and sintering (SLA and SLS): SLA is used to make the prototype of complex parts with difficult CNC appearance and structure, mainly using ABS and PVC materials called photosensitive resin. SLS laser forming is also suitable for TPU soft plastics which can not be processed by CNC, and engineering plastics such as nylon.

(3).Small batch rapid replication by silica gel mold (including vacuum filling and rim): this process takes the model processed by CNC or printed by laser 3D as the core, pours a certain number of silica gel mold, and then injects the liquid plastic into the silica gel mold cavity. After curing, cut the silica gel mold to get the plastic parts. The materials used to make the parts are ABS, PU, PC, nylon, POM and soft PVC

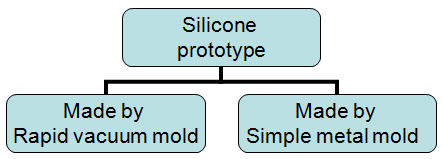

3. Prototype making of silica gel parts:

Silica gel material is soft and its melting point temperature of is low and soft, so CNC or laser 3D printing is generally not available. The main methods to make silicone prototype are vacuum mold and simple mold forming.

The prototypes we have made for our customers are as follows:

CNC Metal prototypes

Sheet metal prototypes

3D sintering prototypes

Silicone prototypes by vacuum mold

CNC plastic prototypes

Laser 3D printing prototypes

Plastic prototypes by vacuum filling

Silicone prototypes by simple mold forming

Surface treatment of prototype

Including 3D printing, CNC processing, surface plating, painting and silk screen printing of the vacuum replica plastic part model.

Including steel parts, aluminum alloy, zinc alloy, stainless steel parts prototype production and painting, electroplating, oxidation, PVD and other surface treatment.

Mestech has a team of engineers specializing in product design, providing small and medium-sized enterprises and customers with one-stop services of product design, product prototype production, plastic and metal production mold production, part mass production and procurement docking.