Silkscreen printing and pattern decoration for plastic parts

Short Description:

Silkscreen printing and pattern decoration are the important post-processing process for plastic parts.

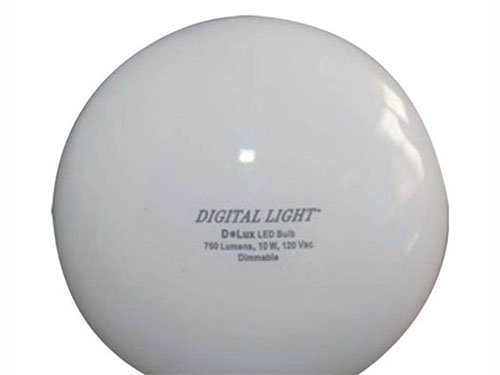

When we sell the products, in order to show the function, appearance and brand information of the products to the customers in a short time, make a deep impression, and attract customers to understand and purchase the products, we usually use silk screen printing, pad printing, laser engraving and hot stamping and other processes to print or engrave on the surface of the products the words, trademarks that express the product feature information, or add decorative patterns for a beautiful look.

For example:

(1).In the product engraving product name, type and brief description, so that customers first understand the function of the product;

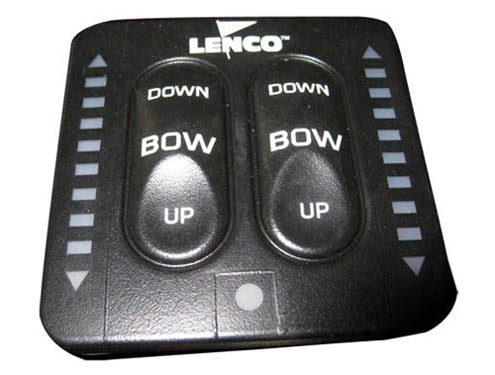

(2).Identify the corresponding function in the button / indicator position of the product to indicate the correct operation.

(3). Print the trademark and information of the manufacturer on the product so as to publicize and promote the brand image.

(4).Printing on the outside of the product, carving beautiful patterns to beautify the appearance, and promoting the language to attract customers.

1. Silkscreen printing

Silkscreen printing is the most commonly used printing method on the surface of plastic products. It is suitable for pattern printing on a plane.

When printing, ink is poured into one end of screen printing plate, and the scraper is used to exert certain pressure on the ink part of screen printing plate. At the same time, the ink moves uniformly towards the other end of screen printing plate. In the movement, the scraper squeezes the ink from the mesh hole of the graphic part to the substrate.

The contents and patterns of silk printing on the surface of parts are various: different combinations of text size, stroke thickness, graphic color, brightness and dumbness, area layout, displaying information of enterprise brand, product function, and beautifying products to attract customers, etc.

Silkscreen printing + UV on plastic parts

Silkscreen printing on metal parts

Multicolor overprint

Two color silkscreen printing on plastic covers

Silkscreen printing consists of five main elements: screen printing plate, scraper, ink, printing table and substrate. There are two types screen printing tool for plastic parts or metal parts : manual silk printer and automatic screen printing machine.

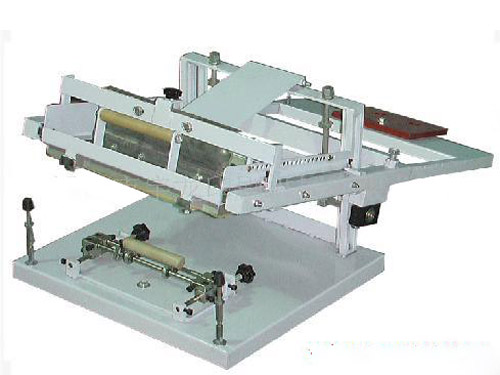

The manual silkscreen printer is a simple tool. It has no power supply to drive the working process, which is realized by manual operation. This kind of device is relatively simple and inexpensive. Artificial silk printers are mostly used for general content and monochrome silkscreen printing. The appearance of the machine is shown in Figure 1.and Figure 2

Figure 1. A manual silkscreen printer

Figure 2. Manual Silkscreen printing

Figure 3. A automatic screen printing machine

Automatic screen printing machine, powered by power supply, most of the screen printing actions are realized by the machine, such as alignment, brushing, lifting and so on. Operators only play the role of monitoring machine work, greatly improving production efficiency, reducing the labor intensity of people. At the same time, the automatic screen printer can achieve multi-color screen printing with uniform inking and accurate alignment. The automatic screen printer is shown in Figure 3.

2.Pad printing

Pad printing is one of the special printing methods. It can print text, graphics and images on the surface of irregular shaped objects. Now it is becoming an important special printing. For example, the text and pattern on the surface of mobile phones are printed in this way, and the surface printing of many electronic products such as computer keyboards, instruments and meters is completed by transfer printing.

Because it has obvious advantages in printing on small area, concave and convex products, it makes up for the shortcomings of screen printing technology. Below are the samples of some pad printed parts.

Pad printing on curve surface

Pad printing on plastic housing

Pad printing on mouse

Multicolor pad printing

Pad printing requires a special transfer machine, which is mainly composed of plate device (including ink feeding device), ink scraper, offset head (usually silica gel material) and printing table

The pad printing machine in working

3. Hot stamping

Hot stamping is also called bronzing or gold stamping, because the tool is made of bronze. Hot stamping is a printing and decoration process. The metal plate is heated, gold foil is printed, and the gold characters or patterns are printed on the printed matter. With the rapid development of hot stamping foil and packaging industry, the application of electrified aluminum foil stamping is more and more extensive.

In the printing process of plastic products, hot stamping and silk printing are relatively easy to operate and widely used printing processes.

They have the characteristics of low cost, easy processing, not easy to fall off, beautiful and generous, and rich performance. They can print various company names, LOGO, propaganda, logos, codes and so on.

Plastic case with hot stamped silver color logo

Hot stamping decorative patter on plastic cover

Gold pattern hot stamping on plastic housing

Multi color fine pattern hot stamping

Principles and characteristics of gold stamping technology:

The hot stamping process uses the principle of hot pressing transfer to transfer the aluminium layer in electrolytic aluminum to the surface of the substrate to form a special metal effect. Because the main material used in the hot stamping is electrolytic aluminum foil, the hot stamping process is also called electrolytic aluminum stamping.

Electrolytic aluminum foil is usually composed of multi-layer materials, the base material is usually P E, followed by separation coating, color coating, metal coating (aluminum plating) and glue coating.

(1) Surface decoration can increase the added value of products. Combined with other processing methods such as bronzing and pressing bump, it can show the strong decorative effect of the product.

(2) To give the products higher anti-counterfeiting performance, such as holographic positioning, hot stamping, trademark identification, etc.

After the product is bronzing, the patterns are clear, beautiful, colorful, wearable and weather resistant. At present, the application of bronzing technology on printed tobacco labels accounts for more than 85%. In graphic design, bronzing can play a key role in highlighting the design theme, especially for the decorative use of trademarks and registered names.

4.Laser engraving

Laser engraving is also called radium carving or laser marking. It is a surface treatment technology based on optical principle. Laser engraving is also a surface treatment process, similar to screen printing, is printed on products or patterns, and the process is different, the price is different.

Laser engraving creates pattern by burning the surface material of a part with a certain thickness along a prescribed path at high temperature of the laser. Compared with silk printing, it has longer wear resistance and lower processing cost.

However, due to the burning of the material of the part matrix itself, the pattern is a single color, which can be divided into two situations:

(1). Parts of opaque materials: single color dark grey;

(2). For transparent parts with surface coating, the pattern is transparent after dark coating on the burning point surface. This feature is often used to make keys with transparent characters.

Laser engraving can be applied to parts made of plastic, hardware, wood and other materials.

The principle of laser processing.

(1) The high intensity focused laser beam emitted by the laser is used to oxidize the material and process it.

(2) The effect of marking is to expose deep substances through evaporation of surface substances, or to cause traces of chemical and physical changes of surface substances by light energy, or to burn some substances by light energy, and to "engrave" traces, or to burn some substances by light energy, to show the required etching graphics and words

Product information laser engraved

Symbol laser engraved on plastic case

Exquisite pattern laser engraved

QR code laser engraved on product

Example: laser engraved keycaps

If you want to make a keyboard, which has letter or number on its each keycap, such as blue, green, red and gray, the key body is white, laser engraving, first spray oil, blue, green, red, gray, each spray the corresponding color, pay attention not to spray on other keys, so that it looks like there are blue keys, green keys and other keys, and then spray a whole layer white (or black), this is a whole white keyboard, and all the blue and green are wrapped under it.

At this time, laser carving can be carried out, using laser technology and ID keyboard maps made of film, carved out the top white oil, such as the processing letter "A", carved out the white strokes, then the next or blue or green will be exposed, thus forming a variety of color letter keys.

At the same time, if you want to be transparent, use PC or PMMA, spray a layer of oil, carve out the font part, then the light below will come out, but at this time to consider the adhesion of various oils, do not spray on the scratch off .

Laser engraved backlit keycaps

Silkscreen printing, pad printing, hot stamping and laser engraving are the four post important decorative processes for the appearance of plastic and metal parts and even the appearance of products. Mestech company provides customers with plastic products molding and hardware molding as well as their screen printing, pad printing, hot stamping and laser carving processing. Please contact us if you need to make this product.