Water transfer printing for plastic products

Short Description:

Water transfer printing is a surface treatment process that uses water pressure and activator to dissolve and transfer the stripping layer on water transfer carrier film to solid surface. Applicable materials: parts surface made of plastic, metal, wood, ceramics, rubber, etc.

Water transfer printing on the surface of plastic products is a special surface decoration process. It is mainly used for surface decoration of plastic products, as well as ceramic and wood products.

What is Water transfer printing

Water transfer printing is also called hydrographics or hydroGraphics, also known as immersion printing, water transfer printing, water transfer imaging, hydro dipping, watermarbling or cubic printing, is a method of applying printed designs to three-dimensional surfaces. The hydrographic process can be used on metal, plastic, glass, hard woods, and various other materials.

Water transfer printing technology is a kind of printing that uses water pressure to hydrolyze the transfer paper/plastic film with color patterns. With the improvement of product packaging and decoration requirements, the use of water transfer printing is more and more extensive. Its indirect printing principle and perfect printing effect solve many problems of product surface decoration, mainly used for transfer printing of various kinds of ceramics, glass flower paper and so on.

The transfer printing has two very important characteristics: one is that it is not limited by the shape of the product, especially complex or large area, super-long, super-wide products can also be decorated.

Plastic products with water transfer printing

Types of water transfer printing

There are two kinds of water transfer technology, one is color pattern transfer, the other is cubic transfer.

The former mainly completes the transfer of characters and pictorial patterns, while the latter tends to complete the transfer on the whole product surface.

Cubic transfer uses a water-based film that is easy to dissolve in water to carry pictures and texts. Due to the excellent tension of the water coating film, it is easy to wind on the surface of the product to form a graphic layer, and the product surface can get a different appearance just like spray painting. Drape on any shape of workpiece to solve the problem of three-dimensional product printing for manufacturers.

The curved surface covering can also add different lines on the product surface, such as leather, wood, emerald and marble lines, etc., and can also avoid the vacancy often seen in the general layout printing. In the printing process,because the product surface does not need to contact with the printing film, it can avoid damaging the product surface and its integrity.

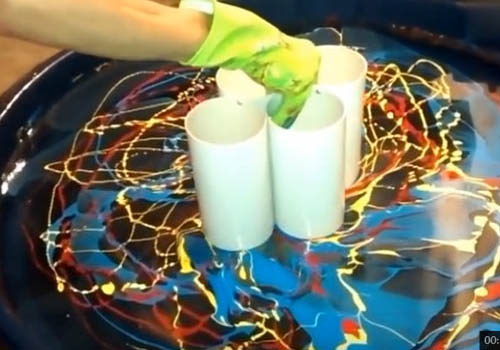

The process of water transfer printing on plastic products

In the process, the substrate piece to be printed first goes through the entire painting process: surface preparation, priming, painting, and clear coating. After painting but before clear coating, the part is ready to be processed. A polyvinyl alcohol hydrographic film, which has been gravure-printed with the graphic image to be transferred, is carefully placed on the water's surface in the dipping tank. The clear film is water-soluble, and dissolves after applying an activator solution. Once dipping is begun, the surface tension of the water will allow the pattern to curve around any shape. Any remaining residue is then rinsed off thoroughly. The ink has already adhered and will not wash off. It is then allowed to dry.

The adhesion is a result of the chemical components of the activator softening the base coat layer and allowing the ink to form a bond with it. One of the most common causes of a failure to achieve adhesion between the two layers is a poorly applied activator. This can be either too much activator being applied or too little.

The other is that it is a more environmentally friendly technology. Waste and waste water will not pollute the environment.

immersing plastic parts into water transfer printing pool

Water transfer printing in the pool

Take out the parts from the pool after being water transfer printed

Advantages of water transfer printing

(1) Beauty: You can transfer any natural lines and photos, pictures and files on the product, so that the product has thedesired landscape color. It has strong adhesion and overall aesthetics.

(2) Innovation: Water transfer printing technology can overcome the problems of complex shape and dead angle which can not be produced by traditional printing and thermal transfer, transfer printing, screen printing and surface painting.

(3) Extensiveness: It is suitable for surface printing of hardware, plastic, leather, glass, ceramics, wood and other products (cloth and paper are not applicable). Because of its beauty, universality and innovation, it has the value added function to the processed products. It can be applied to home decoration, automobile, decoration and other fields, and has diversified patterns, and can be used with other effects.

(4) personalization: whatever you want, I shape myself, and any pattern will be designed with you.

(5) Efficiency: no plate making, direct drawing, immediate transfer printing (the whole process can be completed in 30 minutes, the most suitable proofing).

(6) Advantages: Rapid proofing, surface printing, personalized color painting and non-paper and cloth printing with many small patterns.

(7) the equipment is simple. It can be done on many surfaces that are not resistant to high temperature. There is no requirement for the shape of the transferred object.

Shortcomings of water transfer printing

Water transfer printing technology also has limitations.

(1) Transfer graphics and texts are easily deformed, which is related to the shape of the product and the nature of the water transfer film itself. At the same time, the price is higher, the more complicated the process, the higher the price.

(2) High cost of materials and labor costs.

Application of of water transfer printing

Automotive parts: dashboard, control panel, paper towel plate, tea cup seat, tape rack, rear viewing mirror frame, operation handle, etc.

Electronic products: telephone, pager, video recorder, audio, remote control, mouse, clock, keyboard, camera, hairdryer, etc.

Bedroom supplies: sofa, coffee table, cabinet, chandelier, ashtray, vase, display containers, etc.

Daily-use products: box packaging accessories, tableware handle, glasses box, pen, pen holder, calendar stand, art frame, racket, hair decoration, cosmetic pen, cosmetic box, etc.

Indoor building materials: doors and windows, floors, wall panels, etc.

Mestech specializes in plastic parts forming and water transfer printing and processing services. Please contact us.